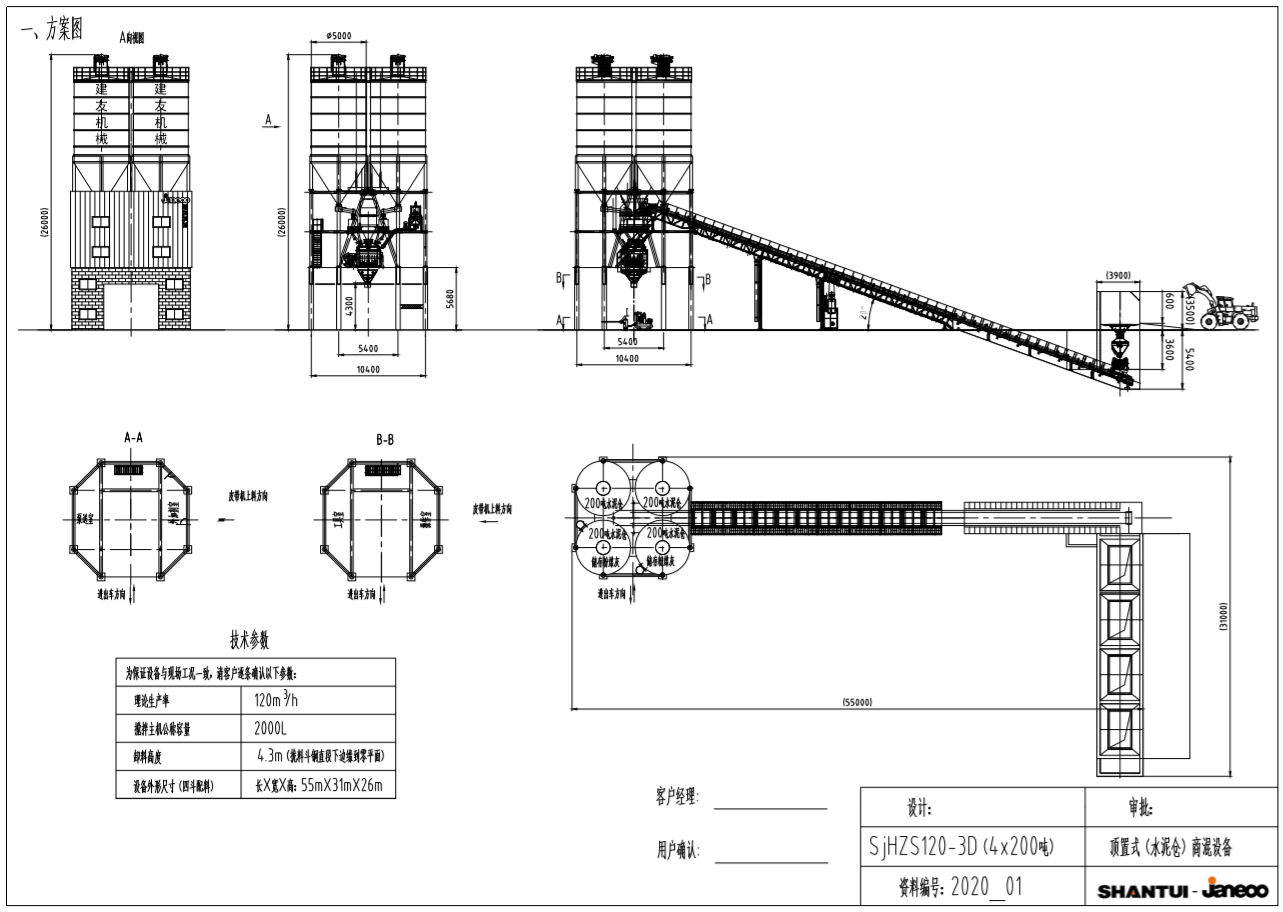

Wholesale Automatic Ready Concrete Batching Plant - D series cement silo top type SjHZS120D – Janeoo

Wholesale Automatic Ready Concrete Batching Plant - D series cement silo top type SjHZS120D – Janeoo Detail:

Specification

|

No. |

Description |

Item |

Origin |

QTY |

Remark |

|

|

1 |

Aggregates batching machine (4 bunkers) |

Storage hopper |

Janeoo |

4 |

Including 2 sand hopper and 2 vibrators | |

| Weighing hopper(2000kg±2%) |

Janeoo |

4 |

||||

| Cylinder |

SMC |

3×4 |

||||

| Sensor |

Toledo |

3×4 |

||||

| Beltmachine(B:1000mm,P:5.5KW) |

Janeoo |

1 |

||||

|

2 |

Inclined belt machine |

Main support |

Janeoo |

1 |

|

|

| Driving device(P:37kW) |

Janeoo |

1 |

||||

| Conveying belt(B:1000mm) |

Janeoo |

1 |

||||

| Washing device |

Janeoo |

1 |

||||

|

3 |

Main building |

Concrete structure |

By customer |

1 |

|

|

| Main frame(2 layers) |

Janeoo |

1 |

||||

| Discharging hopper |

Janeoo |

1 |

||||

| Bag filter |

Janeoo |

1 |

||||

| Decoration(excluding silo)(75mm) |

Janeoo |

1 |

||||

|

4 |

Mixer |

Volume 2.0 m3(Power:2X37kW) |

Janeoo |

1 |

|

|

| Hydraulic structure |

Janeoo |

1 |

||||

| Lubrication system |

Janeoo |

1 |

||||

|

5 |

Mid-storage hopper |

Main hopper |

Janeoo |

1 |

|

|

| Vibrator |

Oli |

1 |

||||

| Cylinder |

SMC |

2 |

||||

|

6 |

Cement weighing system |

Weighing hopper(1000kg±1%) |

Janeoo |

1 |

|

|

| Sensor | Toledo |

3 |

||||

| Valve(DN300) |

WAM |

1 |

||||

| Vibrator |

Oli |

1 |

||||

|

7 |

Powder weighing system

|

Weighing hopper(400kg±1%) |

Janeoo |

1 |

|

|

| Sensor |

Toledo |

3 |

||||

| Valve(DN300) |

WAM |

1 |

||||

| Vibrator |

Oli |

1 |

||||

|

8 |

Water weighing system |

Weighing hopper(500kg±1%) |

Janeoo |

1 |

|

|

| Sensor |

Toledo |

1 |

||||

| Valve (DN150) |

Janeoo |

1 |

||||

| Water pump |

Janeoo |

1 |

||||

| Valve(DN80) |

Janeoo |

1 |

||||

| Pipes |

Janeoo |

1 |

||||

|

9 |

Additive weighing system |

Weighing hopper(50kg±1%) |

Janeoo |

1 |

PE |

|

| sensor |

Toledo |

1 |

||||

| valve (DN100) |

Janeoo |

1 |

||||

| Storage tank 10m3 |

Janeoo |

3 |

||||

| Additive pump |

Janeoo |

3 |

||||

| Pipes |

Janeoo |

3 |

||||

|

10 |

Pneumatic system |

Air compressor(displacement 1.6 m3/min) |

Atlas |

1 |

|

|

| Storage tank 1.0m3+0.3m3 |

Janeoo |

1套 |

||||

| Filter、valve |

SMC |

1 |

||||

|

11 |

Control room |

Concrete structure |

By customer |

1 |

|

|

| Air conditioner |

Haier |

1 |

||||

|

12 |

Electrical system |

Software |

Janeoo |

1 |

||

| Industrial computer |

siemens |

1 |

||||

| UPS power |

Janeoo |

1 |

||||

| Printer |

OKI |

1 |

||||

| Operating carbin |

Janeoo |

1 |

||||

| Main electric component |

schneider |

1 |

||||

| monitoring system 4 cameras and 1 monitor |

Janeoo |

1 |

||||

| List of supporting equipment for selection (the selection part shall be subject to the sales contract) | ||||||

|

No. |

Description |

Item |

Origin |

Qty |

Remark |

|

|

13 |

Cement silo |

300t |

Janeoo |

4 |

Cement density 1.35t/m3 |

|

|

14 |

Accessories |

24㎡ filter(pulse type) |

Janeoo |

4 |

|

|

| Top save valve |

Janeoo |

4 |

||||

| Level meter |

Janeoo |

2X4 |

||||

| Arch breaker |

Janeoo |

4 |

||||

| Valve |

Janeoo |

4 |

||||

|

15 |

Wind chute |

Chute |

Janeoo |

4 |

|

|

| Valve |

WAM |

4 |

||||

Product detail pictures:

Related Product Guide:

We now have several exceptional workers customers good at marketing, QC, and working with types of troublesome trouble during the creation system for Wholesale Automatic Ready Concrete Batching Plant - D series cement silo top type SjHZS120D – Janeoo , The product will supply to all over the world, such as: Palestine, Cambodia, Tajikistan, They're durable modeling and promoting effectively all over the world. Under no circumstances disappearing major functions in a quick time, it's a should for you of excellent good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the company make a terrific efforts to expand its international trade, raise its company profit and raise its export scale. We're confident that we are going to possess a vibrant prospect and to be distributed all over the world within the years to come.

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!