Quality Inspection for Fully Automatic Mixing Plant - Road base Material Mixing Plant – Janeoo

Quality Inspection for Fully Automatic Mixing Plant - Road base Material Mixing Plant – Janeoo Detail:

Product Feature:

1.Concrete mixer adopts lining-plate-free mixing technology, so as to avoid wearing to the mixing blade and lining plate once and for all, making it easy for maintenance.

2.All materials are weighed up in electronic scale, which is controlled by variable frequency converter, featuring high weighing accuracy.

3.Adopting advanced centralized aggregate batching control system, so that batching accuracy and work efficiency of the whole plant can both be improved.

4.Modular structure, easy installation and rapid plant transfer.

5.Product purpose: Adapts to roadbed material pavement of all-grade roads, urban road, playground, wharf, etc.

Technical parameters

| Model | SjWBZ300 | SjWBZ400 | SjWBZ500 | SjWBZ600 | SjWBZ700 | SjWBZ800 | |

| Rated capacity(t/h) | 300 | 400 | 500 | 600 | 700 | 800 | |

|

Mixer |

Mixer rate power(kW) | 2X22 | 2X22 | 2X30 | 2X37 | 2X37 | 2X45 |

| Aggregate size(mm) | ≤50 | ≤50 | ≤50 | ≤50 | ≤50 | ≤50 | |

| Aggregate Bin Capacity (m³) | 4X12 | 4X12 | 4X12 | 5X12 | 5X12 | 5X15 | |

| Belt conveyance (t/h) | 300 | 400 | 500 | 600 | 700 | 800 | |

|

Weighing accuracy |

Aggregate | ±2% | ±2% | ±2% | ±2% | ±2% | ±2% |

| Cement | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | |

| Water | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | |

| Total power(kW) | 125 | 125 | 149 | 166 | 166 | 198 | |

| Discharge height(m) | 3.6 | 3.6 | 3.6 | 3.6 | 3.6 | 3.6 | |

All specification is subject to modification.

Product Components

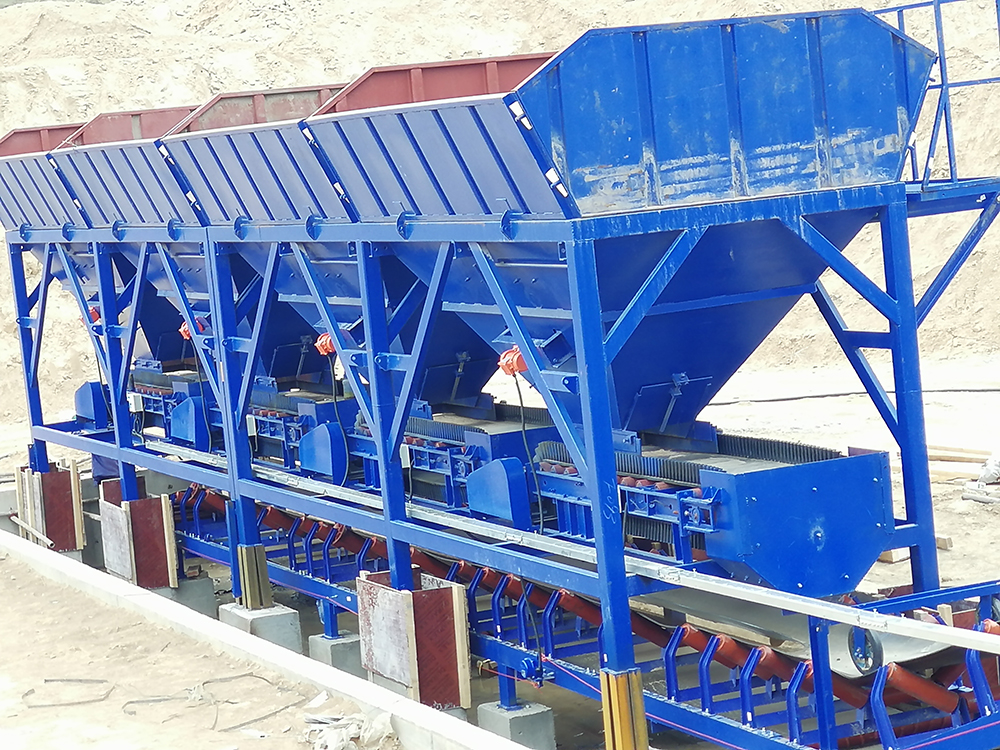

Product detail pictures:

Related Product Guide:

With our leading technology at the same time as our spirit of innovation,mutual cooperation, benefits and growth, we're going to build a prosperous future together with your esteemed firm for Quality Inspection for Fully Automatic Mixing Plant - Road base Material Mixing Plant – Janeoo , The product will supply to all over the world, such as: Namibia, Bhutan, Brisbane, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!