OEM/ODM Manufacturer Hzs50 Stationary Concrete Batching Plant - M series SjHZS120M specifications – Janeoo

OEM/ODM Manufacturer Hzs50 Stationary Concrete Batching Plant - M series SjHZS120M specifications – Janeoo Detail:

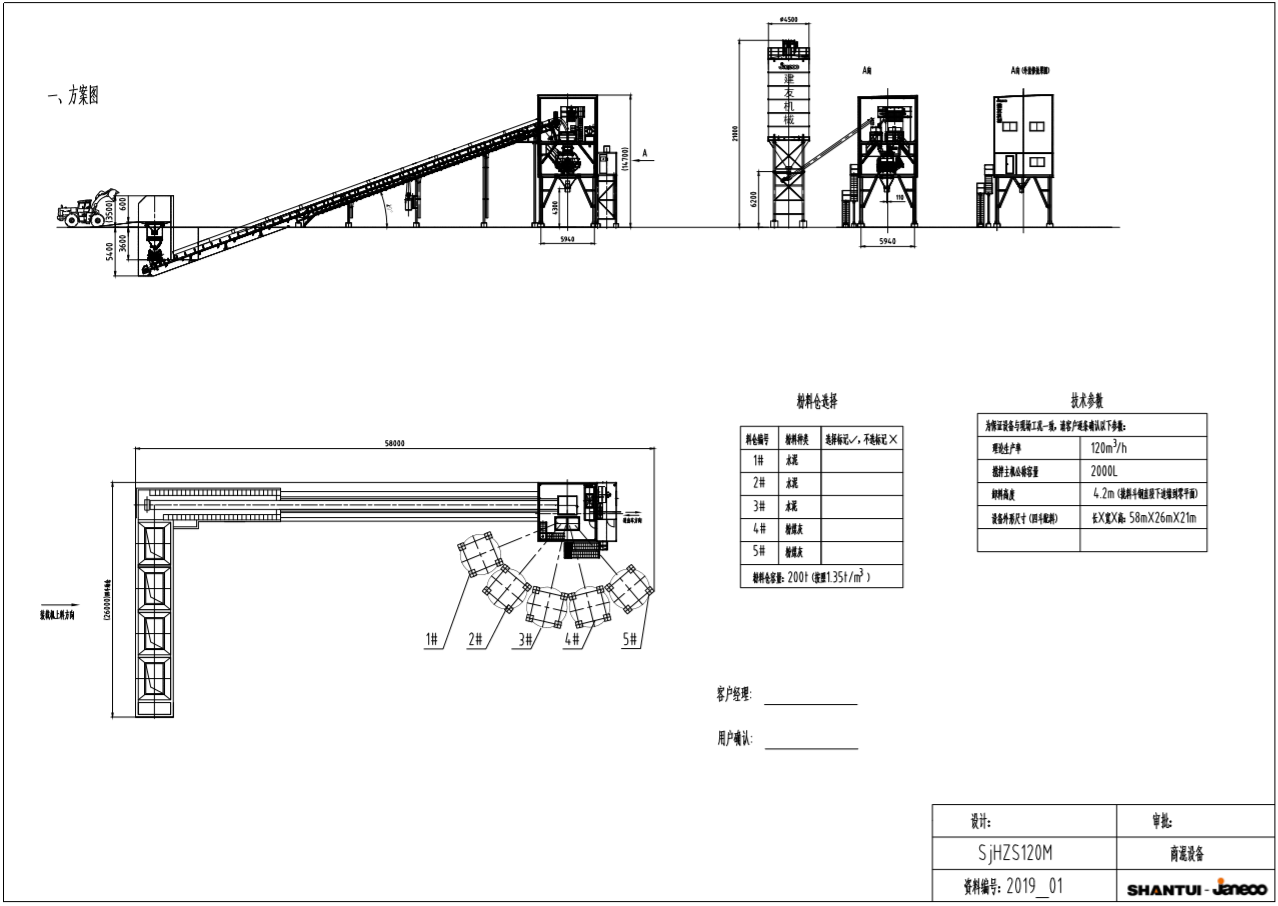

SjHZS120M configuration

|

No. |

Description |

Item |

Origin |

Qty |

Remark |

|

|

1 |

Aggregates batching system (4 hoppers ground type) |

Storage hopper |

Janeoo |

4 |

2 vibrator for 2 sand hoppers | |

| Weighing hopper(2000kg±2%) |

Janeoo |

4 |

||||

| cylinder |

SMC |

3×4 |

||||

| Sensor |

Toledo |

3×4 |

||||

| Belt machine(B:1000mm,P:5.5KW) |

Janeoo |

1 |

||||

|

2 |

Inclined belt machine |

Main support |

Janeoo |

1 |

|

|

| Driving device(P:37kW) |

Janeoo |

1 |

||||

| Belt(B:1000mm) |

Janeoo |

1 |

||||

| Water washing device |

Janeoo |

1 |

||||

|

3 |

Main building |

Main structure(2 layers platform) |

Janeoo |

1 |

|

|

| Discharging hopper |

Janeoo |

1 |

||||

| Bag type filter |

Janeoo |

1 |

||||

| Decoration |

Janeoo |

1 |

||||

|

4 |

High end mixer |

V:2.0 m3(P:2X37kW) |

Janeoo |

1 |

|

|

| Pneumatical Discharging structure |

Janeoo |

1 |

||||

| Pneumatic sealing system |

Janeoo |

1 |

||||

|

5 |

Middle hopper |

Storage hopper |

Janeoo |

1 |

|

|

| vibrator |

Janeoo |

1 |

||||

| cylinder |

SMC |

2 |

||||

|

6 |

Cement weighing system |

Weighing hopper(1000kg±1%) |

Janeoo |

1 |

|

|

| sensor |

Toledo |

3 |

||||

| Discharging valve(DN300) |

WAM |

1 |

||||

| vibrator |

Oli |

1 |

||||

|

7 |

Powder weighing system

|

Weighing hopper(400kg±1%) |

Janeoo |

1 |

|

|

| sensor |

Toledo |

3 |

||||

| Discharging valve(DN300) |

WAM |

1 |

||||

| vibrator |

Oli |

1 |

||||

|

8 |

Water weighing system |

Weighing hopper(500kg±1%) |

Janeoo |

1 |

|

|

| sensor |

Toledo |

1 |

||||

| discharging valve (DN150) |

Janeoo |

1 |

||||

| Water pump |

Janeoo |

1 |

||||

| Weighing valve(DN80) |

Janeoo |

1 |

||||

| Weighing pipes |

Janeoo |

1 |

||||

|

9 |

Additive weighing system |

Weighing hopper(50kg±1%) |

Janeoo |

1 |

Pe additive tank |

|

| sensor |

Toledo |

1 |

||||

| Discharging valve |

Janeoo |

1 |

||||

| Storage tank(V:10m3) |

Janeoo |

2 |

||||

| Additive pump |

Janeoo |

2 |

||||

| Weighing pipes |

Janeoo |

2 |

||||

|

10 |

Pneumatic system |

Air compressor(displacement:1.6 m3/min) | Atlas |

1 |

|

|

| Sotrage tank 1m3+0.3m3 |

Janeoo |

1套 |

||||

| Filter and valve |

SMC |

1 |

||||

|

11 |

Control room |

decoration |

Janeoo |

1 |

|

|

| Air conditioner |

Haier |

1 |

||||

|

12 |

Electrical system |

software |

Janeoo |

1 |

||

| Industrial computer and monitor |

Siemens |

1 |

||||

| UPS power |

Janeoo |

1 |

||||

| Printer |

OKI |

1 |

||||

| Electrical carbin and table |

Janeoo |

1 |

||||

| Main electric components |

schneider |

1 |

||||

| Monitoring system(1 monitor+4 cameras) |

Janeoo |

1 |

||||

| Optional | ||||||

|

No. |

Description |

Item |

Origin |

Qty |

Remark |

|

|

13 |

Cement silo |

200t |

Janeoo |

5 |

Cement density 1.35t/m3 |

|

| Maintenance platform |

Janeoo |

1 |

|

|||

|

14 |

Accessoies |

24㎡ filter |

Janeoo |

5 |

|

|

| Safe valve on the top |

Janeoo |

5 |

||||

| Level meter |

Janeoo |

2X5 |

||||

| Arch breaker |

Janeoo |

5 |

||||

| Manual valve |

Janeoo |

5 |

||||

|

15 |

Screw conveyor |

φ273X11m |

Janeoo |

3 |

cement |

|

| φ219X11m |

Janeoo |

2 |

powder |

|||

Product detail pictures:

Related Product Guide:

We normally think and practice corresponding towards the change of circumstance, and grow up. We aim at the achievement of a richer mind and body plus the living for OEM/ODM Manufacturer Hzs50 Stationary Concrete Batching Plant - M series SjHZS120M specifications – Janeoo , The product will supply to all over the world, such as: Cape Town, Eindhoven, Angola, Due to our strict pursues in quality, and after-sale service, our product gets more and more popular around the world. Many clients came to visit our factory and place orders. And there are also many foreign friends who came for sight seeing, or entrust us to buy other stuff for them. You are most welcome to come to China, to our city and to our factory!

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!