OEM Customized Best Sale Concrete Batching Plant - M series SjHZS120M specifications – Janeoo

OEM Customized Best Sale Concrete Batching Plant - M series SjHZS120M specifications – Janeoo Detail:

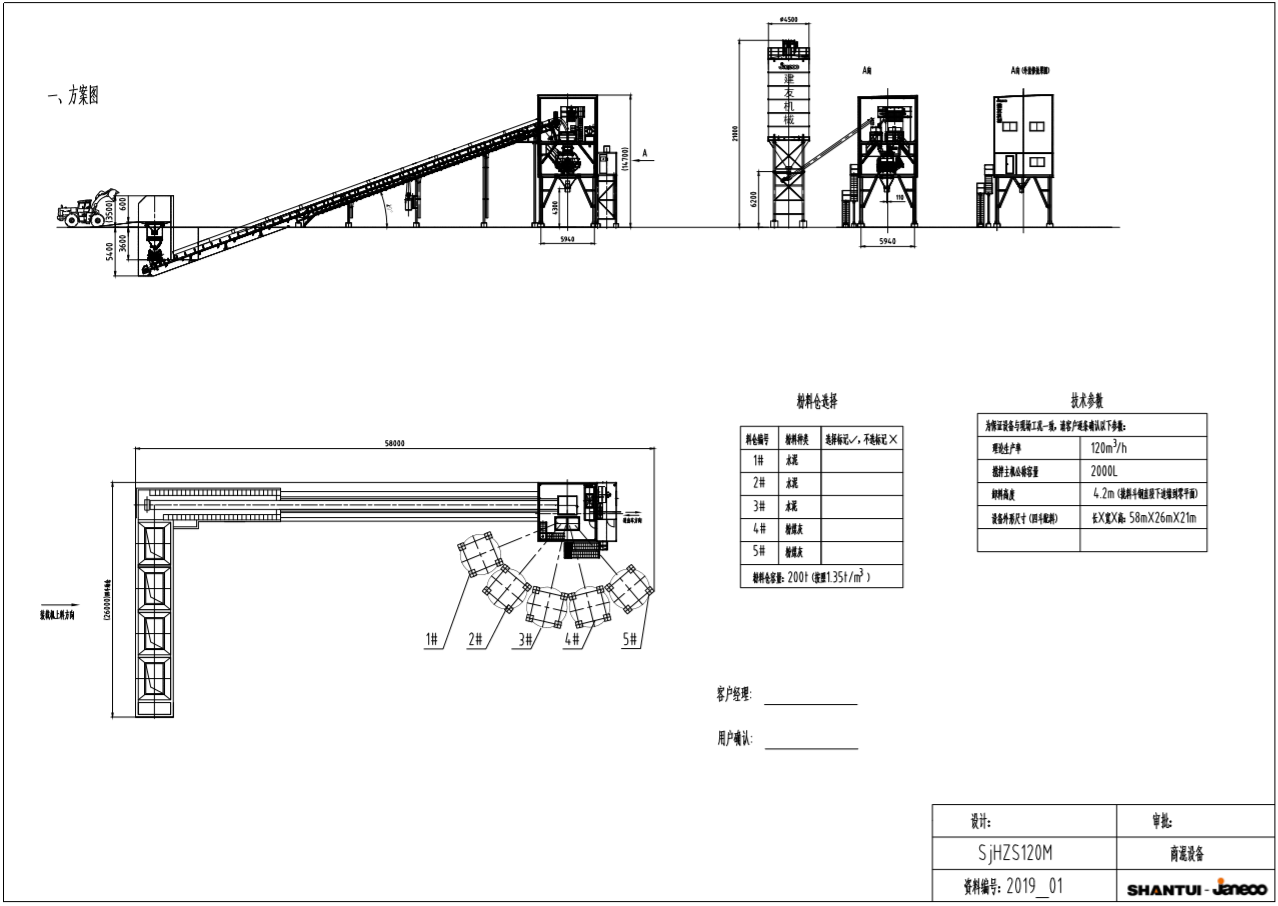

SjHZS120M configuration

|

No. |

Description |

Item |

Origin |

Qty |

Remark |

|

|

1 |

Aggregates batching system (4 hoppers ground type) |

Storage hopper |

Janeoo |

4 |

2 vibrator for 2 sand hoppers | |

| Weighing hopper(2000kg±2%) |

Janeoo |

4 |

||||

| cylinder |

SMC |

3×4 |

||||

| Sensor |

Toledo |

3×4 |

||||

| Belt machine(B:1000mm,P:5.5KW) |

Janeoo |

1 |

||||

|

2 |

Inclined belt machine |

Main support |

Janeoo |

1 |

|

|

| Driving device(P:37kW) |

Janeoo |

1 |

||||

| Belt(B:1000mm) |

Janeoo |

1 |

||||

| Water washing device |

Janeoo |

1 |

||||

|

3 |

Main building |

Main structure(2 layers platform) |

Janeoo |

1 |

|

|

| Discharging hopper |

Janeoo |

1 |

||||

| Bag type filter |

Janeoo |

1 |

||||

| Decoration |

Janeoo |

1 |

||||

|

4 |

High end mixer |

V:2.0 m3(P:2X37kW) |

Janeoo |

1 |

|

|

| Pneumatical Discharging structure |

Janeoo |

1 |

||||

| Pneumatic sealing system |

Janeoo |

1 |

||||

|

5 |

Middle hopper |

Storage hopper |

Janeoo |

1 |

|

|

| vibrator |

Janeoo |

1 |

||||

| cylinder |

SMC |

2 |

||||

|

6 |

Cement weighing system |

Weighing hopper(1000kg±1%) |

Janeoo |

1 |

|

|

| sensor |

Toledo |

3 |

||||

| Discharging valve(DN300) |

WAM |

1 |

||||

| vibrator |

Oli |

1 |

||||

|

7 |

Powder weighing system

|

Weighing hopper(400kg±1%) |

Janeoo |

1 |

|

|

| sensor |

Toledo |

3 |

||||

| Discharging valve(DN300) |

WAM |

1 |

||||

| vibrator |

Oli |

1 |

||||

|

8 |

Water weighing system |

Weighing hopper(500kg±1%) |

Janeoo |

1 |

|

|

| sensor |

Toledo |

1 |

||||

| discharging valve (DN150) |

Janeoo |

1 |

||||

| Water pump |

Janeoo |

1 |

||||

| Weighing valve(DN80) |

Janeoo |

1 |

||||

| Weighing pipes |

Janeoo |

1 |

||||

|

9 |

Additive weighing system |

Weighing hopper(50kg±1%) |

Janeoo |

1 |

Pe additive tank |

|

| sensor |

Toledo |

1 |

||||

| Discharging valve |

Janeoo |

1 |

||||

| Storage tank(V:10m3) |

Janeoo |

2 |

||||

| Additive pump |

Janeoo |

2 |

||||

| Weighing pipes |

Janeoo |

2 |

||||

|

10 |

Pneumatic system |

Air compressor(displacement:1.6 m3/min) | Atlas |

1 |

|

|

| Sotrage tank 1m3+0.3m3 |

Janeoo |

1套 |

||||

| Filter and valve |

SMC |

1 |

||||

|

11 |

Control room |

decoration |

Janeoo |

1 |

|

|

| Air conditioner |

Haier |

1 |

||||

|

12 |

Electrical system |

software |

Janeoo |

1 |

||

| Industrial computer and monitor |

Siemens |

1 |

||||

| UPS power |

Janeoo |

1 |

||||

| Printer |

OKI |

1 |

||||

| Electrical carbin and table |

Janeoo |

1 |

||||

| Main electric components |

schneider |

1 |

||||

| Monitoring system(1 monitor+4 cameras) |

Janeoo |

1 |

||||

| Optional | ||||||

|

No. |

Description |

Item |

Origin |

Qty |

Remark |

|

|

13 |

Cement silo |

200t |

Janeoo |

5 |

Cement density 1.35t/m3 |

|

| Maintenance platform |

Janeoo |

1 |

|

|||

|

14 |

Accessoies |

24㎡ filter |

Janeoo |

5 |

|

|

| Safe valve on the top |

Janeoo |

5 |

||||

| Level meter |

Janeoo |

2X5 |

||||

| Arch breaker |

Janeoo |

5 |

||||

| Manual valve |

Janeoo |

5 |

||||

|

15 |

Screw conveyor |

φ273X11m |

Janeoo |

3 |

cement |

|

| φ219X11m |

Janeoo |

2 |

powder |

|||

Product detail pictures:

Related Product Guide:

Persisting in "High top quality, Prompt Delivery, Aggressive Price", now we have established long-term cooperation with customers from the two overseas and domestically and get new and aged clients' large comments for OEM Customized Best Sale Concrete Batching Plant - M series SjHZS120M specifications – Janeoo , The product will supply to all over the world, such as: Mombasa, Comoros, Islamabad, Each year, many of our customers would visit our company and achieve great business advancements working with us. We sincerely welcome you to visit us at any time and together we will prevail to a greater success in the hair industry.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!