High Quality China Supplier Dry Mix Concrete Batch Plant - SjGTD060-3G Tower Type Dry Mortar Batching Plant – Janeoo

High Quality China Supplier Dry Mix Concrete Batch Plant - SjGTD060-3G Tower Type Dry Mortar Batching Plant – Janeoo Detail:

Main specifications

1.main specifications

Theoretical productivity 60-80t/h

Mixer SjGD4500-5B

aggregates measuring accuracy±2%

Cement measuring accuracy ±1%

additive measuring accuracy ±0.5%

Sand silo volume 4X50m3

Cement silo volume 2X85m3 +2X42m3

Cement silo volume 2X85m3 +2X42m3

Packing capacity 200-300bags/h/set

Packing capacity 200-300bags/h/set

1.Sand hoisting elevator

| Type | TB60 |

| Hoist speed | 1.1m/s |

| Theoretical capacity | 60m3/h |

| Motor power | 18.5kW |

2.Sand batching chute pipe

| chute diameter | 323mm |

3.Cement batching screw conveyor

| screw diameter | 219mm |

| capacity | 60t/h |

| Motor power | 7.5KW |

4.Fly ash batching screw conveyor

| screw diameter | 219mm |

| capacity | 60t/h |

| Motor power | 7.5kW |

5.Thickening powder batching screw conveyor

| screw diameter | 219mm |

| capacity | 60t/h |

| Motor power | 7.5kW |

6.aggregates measuring hopper

| type | electronic scale |

| Max value | 4000kg |

| accuracy | ±2% |

7.cement measuring hopper

| type | electronic scale |

| Max value | 2000kg |

| accuracy | ±1% |

8.additive measuring hopper

| type | electronic scale |

| Max value | 150kg |

| accuracy | ±0.5% |

9.mixer system

| Mixer | SjGD4500-5B |

| motor power | 90KW |

| blade power | 4×5.5KW |

10.impeller feeder

| diameter | 400mm |

| motor power | 3KW |

| capacity | 50m3/h |

11.packing machine

|

packing capacity |

200~300 bags/h/set |

|

each weight |

25~50Kg |

12.belt machine

| belt machine | 2KW |

13.production screw conveyor

| type | GX500 |

| capacity | 70m3/h |

| motor power | motor power |

14bulk machine

15.production hoist elevator16.2 production screw conveyor 217.electrical system19.electrical system

The system is powered by ac 380V and 50Hz three-phase four (five) wire system.

20.computer control

computer control

21.cycle time

auto:180s

| capacity | 100t/h |

| flexible distance of discharging gate | 1200mm |

| motor power | 0.55kW |

| filter fan power | 2.2kW |

| type | TB110 |

| hoist speed | 1.1m/s |

| capacity | 110m3/h |

| motor power | 22kW |

| screw diameter | GX500 |

| capacity | 70m3/h |

| motor power | 7.5KW |

| air compressor power | 37kW |

| pressure | 7.5KW |

Description

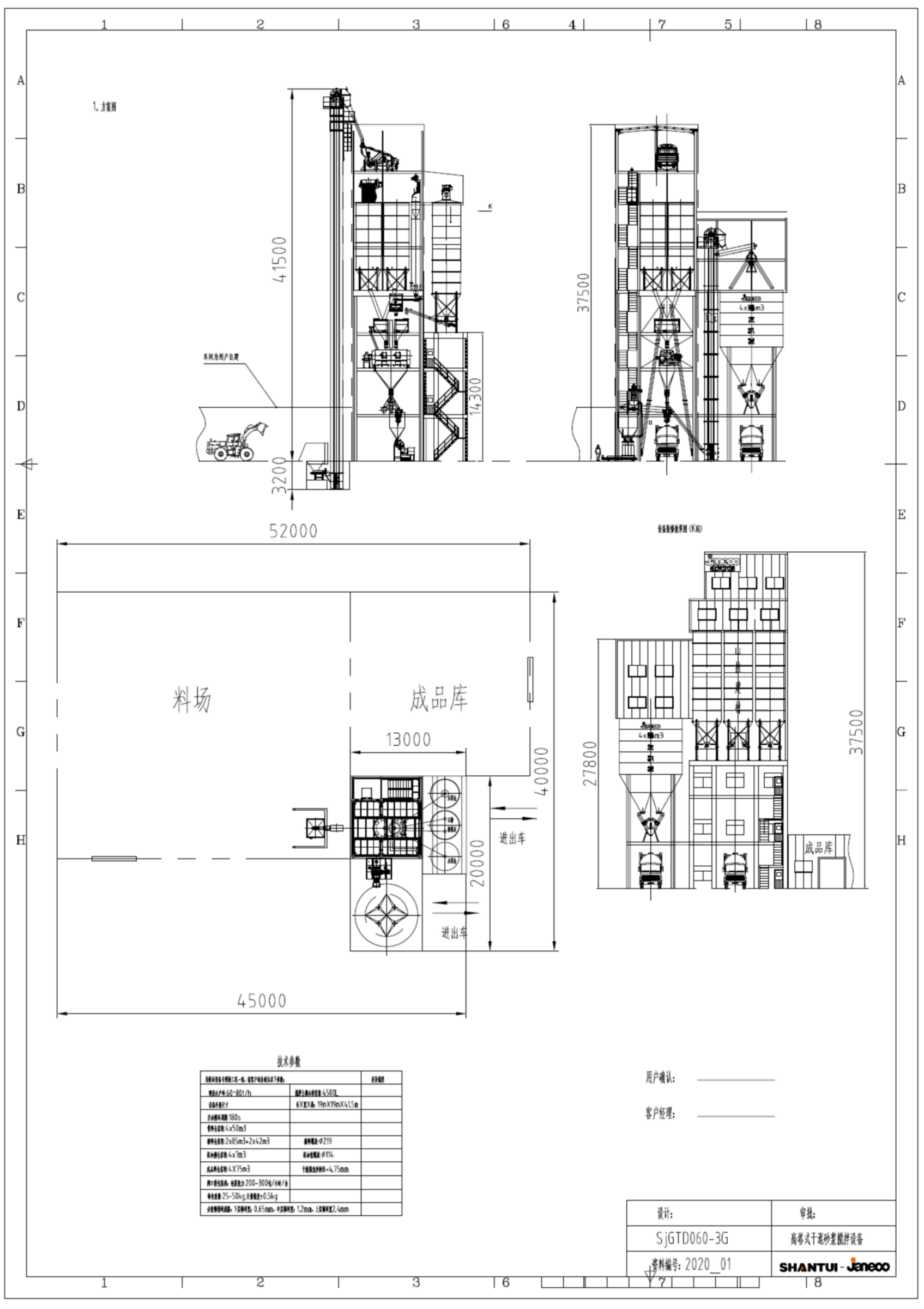

Sjgtd060-3g dry mortar batching equipment adopts tower structure, with large productivity, energy saving and environmental protection, stable and reliable characteristics, mainly used for mixing ordinary dry mortar.

The main equipment adopts tower structure, with 4 sand silos, 4 powder silos, 4 additive silos and 4 finished product silos. Sand for ordinary wire use is lifted by bucket machine and stored in sand bin after graded screening.Powder is delivered to the powder bin by bulk tanker.The additive is lifted to the additive storehouse by the electric lifting device and put into the additive storehouse manually.

Sand adopts sliding pipe batching, powder material, additives adopt spiral conveyor batching.

The measuring bucket adopts electronic scale to measure, which has high measuring precision and small error.

The control system adopts manual and automatic control.The system has perfect self-locking and inter-locking functions to ensure accurate and reliable operation of the system, and has common fault detection and alarm functions.

Configuration

| Standard equipment | ||||

| No. | Description | Item |

Qty |

Remark |

|

1 |

dry sand hoist device |

1 |

|

|

| elevator(42m) |

1 |

|||

| ladder and platform |

1 |

|||

| chute of feeding and discharging |

1 |

|||

|

2 |

graded screen device |

1 |

|

|

| 3 layers vibrating screen(2×3.6KW)lower:0.65mm,mid:1.2mm,upper 2.4mm |

1 |

|||

| chute pipe |

1 |

|||

|

3 |

sand silo filter |

1 |

|

|

| chute pipe φ325 |

4 |

|||

| pneumatic valve(DN300) |

4 |

|||

| insert valve |

4 |

|||

| pulse back flush filter HMC48 |

1 |

|||

|

4 |

sand scale |

1 |

|

|

| max value 4000kg |

1 |

|||

| pressure sensor |

3 |

|||

| sensor joints |

3 |

|||

| pneumatic valve(DN300) |

2 |

|||

| vibrator MVE60/3 |

1 |

|||

|

5 |

cement scale |

1 |

|

|

| max value 2000kg |

1 |

|||

| pressure sensor |

3 |

|||

| sensor joints |

3 |

|||

| pneumatic valve(DN300) |

2 |

|||

| vibrator MVE60/3 |

1 |

|||

|

6 |

additive scale |

1 |

|

|

| max value 150kg |

1 |

|||

| pressure sensor |

3 |

|||

| pneumatic valve(DN200) |

1 |

|||

| vibrator MVE60/3 |

1 |

|||

|

7 |

manual feeding device |

1 |

|

|

| feeding hopper and cover |

1 |

|||

| pneumatic valve(DN200) |

1 |

|||

|

8 |

additive filter |

1 |

|

|

| pneumatic valve(DN150) |

4 |

|||

| additive silo filter |

1 |

|||

|

9 |

mixing system(V:4500L) |

1 |

|

|

| driving device 90KW |

1 |

|||

| mixing device |

1 |

|||

| high speed rotary scraper 5.5KW |

4 |

|||

| discharging gate |

1 |

|||

| mixing tank |

1 |

|||

| sample device |

1 |

|||

|

10 |

Main hopper and bulk |

1 |

|

|

| hopper body |

1 |

|||

| vibrator MVE 60/3 |

2 |

|||

| impelled feeder |

1 |

|||

| pneumatic 4 phases |

1 |

|||

| rotary level meter ILTC0 |

1 |

|||

| bulk machine |

1 |

|||

|

11 |

production packing machine |

|

|

|

| hopper body |

1 |

|||

| rotary level meter ILTC0 |

2 |

|||

| vibrator MVE 60/3 |

2 |

|||

| 2 exits packing machine |

1 |

|||

| production belt machine (B=650mm,2.2kw) |

1 |

|||

|

12 |

production hoist and distributer |

1 |

|

|

| elevator(24m,15kw) |

1 |

|||

| ladder and platform |

1 |

|||

| chute of feeding and discharging |

1 |

|||

| screw support |

1 |

|||

| rotary distrubuter 0.75KW |

1 |

|||

|

13 |

production bulk |

1 |

|

|

| pneumatic insert valve |

4 |

|||

| pneumatic valve(DN300) |

4 |

|||

| tansition hopper |

1 |

|||

| bulk machine |

1 |

|||

|

14 |

packing filter device |

1 |

|

|

| pulse back flush filter(1.5kw) |

1 |

|||

| filter pipes |

1 |

|||

| manual valve(DN150) |

1 |

|||

|

15 |

pneumatic system |

1 |

|

|

| air compressor |

1 |

|||

| storage tank 1m3 |

1 |

|||

| Storage tank 0.3m3 |

2 |

|||

| main filter |

1 |

|||

| dryer |

1 |

|||

| joints |

1 |

|||

|

16 |

control system |

1 |

|

|

| industrial computer |

2 |

|||

| software |

2 |

|||

| electric components |

1 |

|||

| 19LED monitor |

2 |

|||

| printer |

1 |

|||

| power supply |

1 |

|||

| operation table |

1 |

|||

| electrical cabinet |

1 |

|||

| wires and cables |

1 |

|||

|

17 |

surveillance system |

1 |

|

|

| color cameras |

4 |

|||

| cemera lens |

4 |

|||

| LED monitor |

1 |

|||

| insert DV |

1 |

|||

|

18 |

Main steel structure |

|

|

|

| chassis |

1 |

|||

| ladder |

1 |

|||

| support |

1 |

|||

| storage delivery and outer decoration | ||||

|

19 |

cement screw conveyor | φ219X6000mm |

2 |

|

|

20 |

cement screw conveyor | φ219X5000mm |

2 |

|

|

21 |

机additive screw conveyor | φ114x3000mm |

2 |

|

|

22 |

additive screw conveyor | φ114x2000mm |

2 |

|

|

23 |

production screw conveyor | GX500-4500 |

1 |

|

|

24 |

production screw conveyor | GX500-2500 |

1 |

|

|

25 |

Sand storage silo |

4 |

|

|

| V:50m3 |

4 |

|||

| manual valve |

4 |

|||

| rotary level meter |

8 |

|||

|

26 |

cement storage silo |

2 |

|

|

| V:85m3 |

2 |

|||

| arch breaker |

2 |

|||

| manual valve(DN300) |

2 |

|||

| rotary level meter |

4 |

|||

| safe valve |

2 |

|||

| silo top pulse back flush filter |

2 |

|||

|

27 |

cement storage silo |

1 |

|

|

| V:2x42m3,insulation silo |

1 |

|||

| arch breaker |

2 |

|||

| manual valve(DN300) |

2 |

|||

| rotary level meter |

4 |

|||

| safe valve |

2 |

|||

| silo top pulse back flush filter |

2 |

|||

|

28 |

production storage silo |

1 |

|

|

| V:4x75m3,insulation silo |

1 |

|||

| pulse back flush filter(1.5kw) |

1 |

|||

| arch breaker |

4 |

|||

| manual valve |

4 |

|||

| rotary level meter |

8 |

|||

|

29 |

additive silo |

4 |

|

|

| V:7m3 |

4 |

|||

| rotary level meter |

4 |

|||

| vibrator MVE 60/3 |

4 |

|||

| manual valve(DN300) |

4 |

|||

|

30 |

electric hoist device |

1 |

|

|

| electric hoist |

1 |

|||

| rail, cage |

1 |

|||

|

31 |

decoration |

decoration 1500m2,(0.5mm) |

1 |

|

| body frame |

1 |

|||

Product detail pictures:

Related Product Guide:

Our purpose would be to offer good quality products at competitive price ranges, and top-notch support to clients around the whole world. We're ISO9001, CE, and GS certified and strictly adhere to their good quality specifications for High Quality China Supplier Dry Mix Concrete Batch Plant - SjGTD060-3G Tower Type Dry Mortar Batching Plant – Janeoo , The product will supply to all over the world, such as: Portland, Angola, Morocco, Although continuous opportunity, we have now now developed serious a friendly relationship with many oversea merchants, such as ones through Virginia. We securely assume that the merchandise regarding t shirt printer machine is often good through a great number of having its good quality and also cost.

This supplier stick to the principle of "Quality first, Honesty as base", it is absolutely to be trust.