Wholesale Price China Concrete Batching Plant For Road Maintance - Road base Material Mixing Plant – Janeoo

Wholesale Price China Concrete Batching Plant For Road Maintance - Road base Material Mixing Plant – Janeoo Detail:

Product Feature:

1.Concrete mixer adopts lining-plate-free mixing technology, so as to avoid wearing to the mixing blade and lining plate once and for all, making it easy for maintenance.

2.All materials are weighed up in electronic scale, which is controlled by variable frequency converter, featuring high weighing accuracy.

3.Adopting advanced centralized aggregate batching control system, so that batching accuracy and work efficiency of the whole plant can both be improved.

4.Modular structure, easy installation and rapid plant transfer.

5.Product purpose: Adapts to roadbed material pavement of all-grade roads, urban road, playground, wharf, etc.

Technical parameters

| Model | SjWBZ300 | SjWBZ400 | SjWBZ500 | SjWBZ600 | SjWBZ700 | SjWBZ800 | |

| Rated capacity(t/h) | 300 | 400 | 500 | 600 | 700 | 800 | |

|

Mixer |

Mixer rate power(kW) | 2X22 | 2X22 | 2X30 | 2X37 | 2X37 | 2X45 |

| Aggregate size(mm) | ≤50 | ≤50 | ≤50 | ≤50 | ≤50 | ≤50 | |

| Aggregate Bin Capacity (m³) | 4X12 | 4X12 | 4X12 | 5X12 | 5X12 | 5X15 | |

| Belt conveyance (t/h) | 300 | 400 | 500 | 600 | 700 | 800 | |

|

Weighing accuracy |

Aggregate | ±2% | ±2% | ±2% | ±2% | ±2% | ±2% |

| Cement | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | |

| Water | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | |

| Total power(kW) | 125 | 125 | 149 | 166 | 166 | 198 | |

| Discharge height(m) | 3.6 | 3.6 | 3.6 | 3.6 | 3.6 | 3.6 | |

All specification is subject to modification.

Product Components

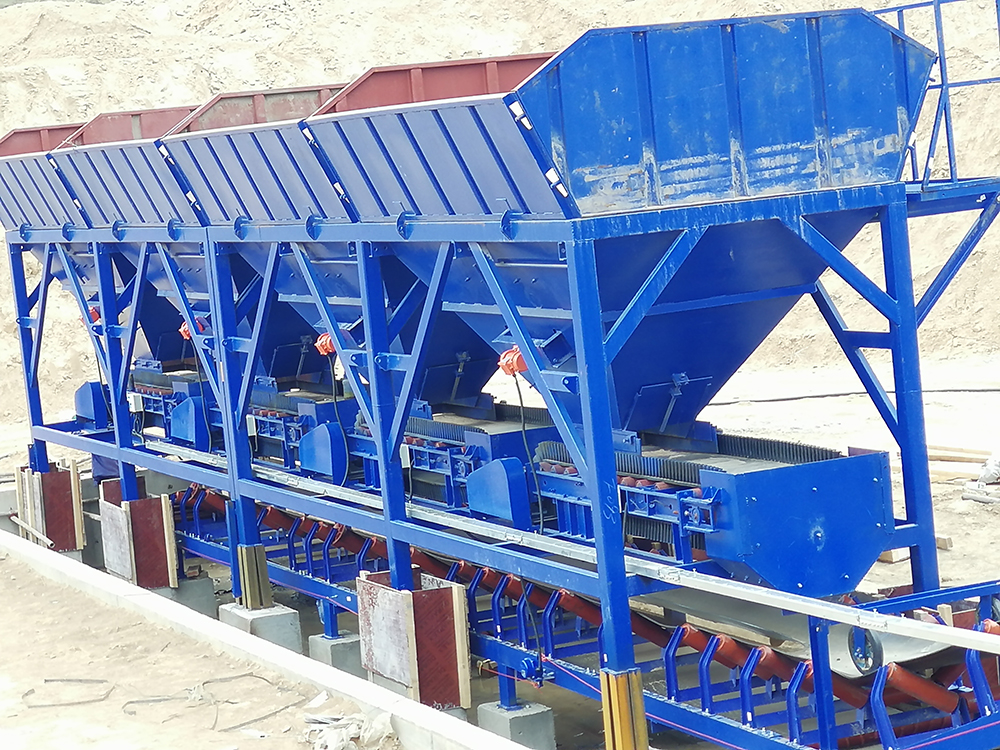

Product detail pictures:

Related Product Guide:

Adhering to your principle of "quality, assistance, performance and growth", we have now gained trusts and praises from domestic and international customer for Wholesale Price China Concrete Batching Plant For Road Maintance - Road base Material Mixing Plant – Janeoo , The product will supply to all over the world, such as: Mumbai, Jeddah, Germany, Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements. We can provided good quality with competitive price for you personally.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.