Reliable Supplier Concrete Mixer And Concrete Batching Plant - M series SjHZS120M specifications – Janeoo

Reliable Supplier Concrete Mixer And Concrete Batching Plant - M series SjHZS120M specifications – Janeoo Detail:

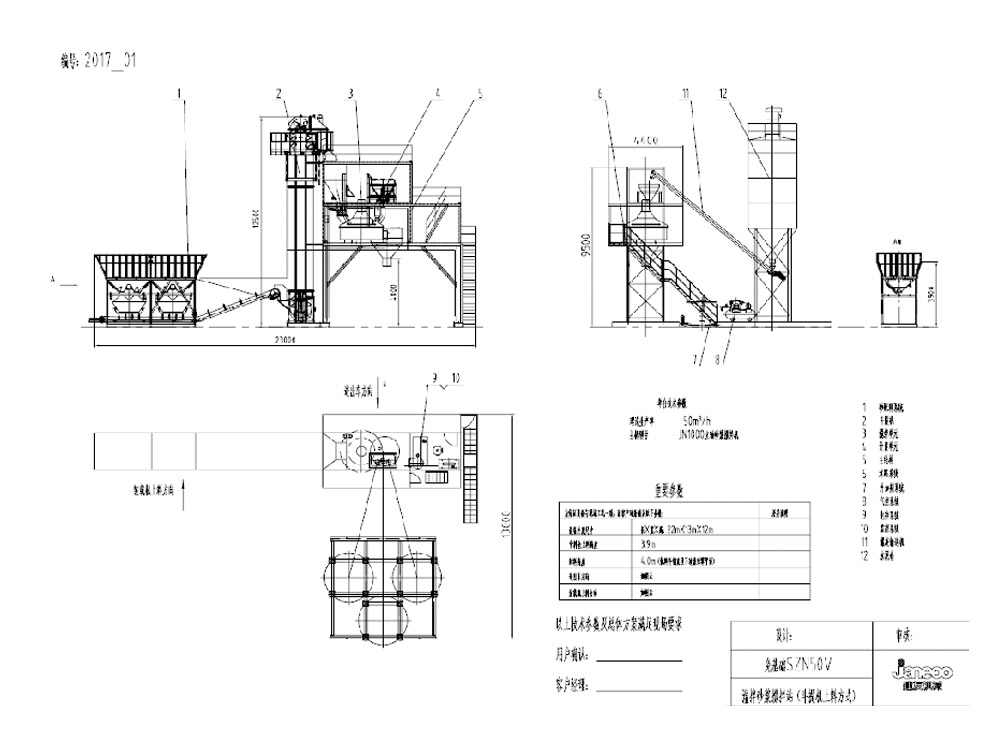

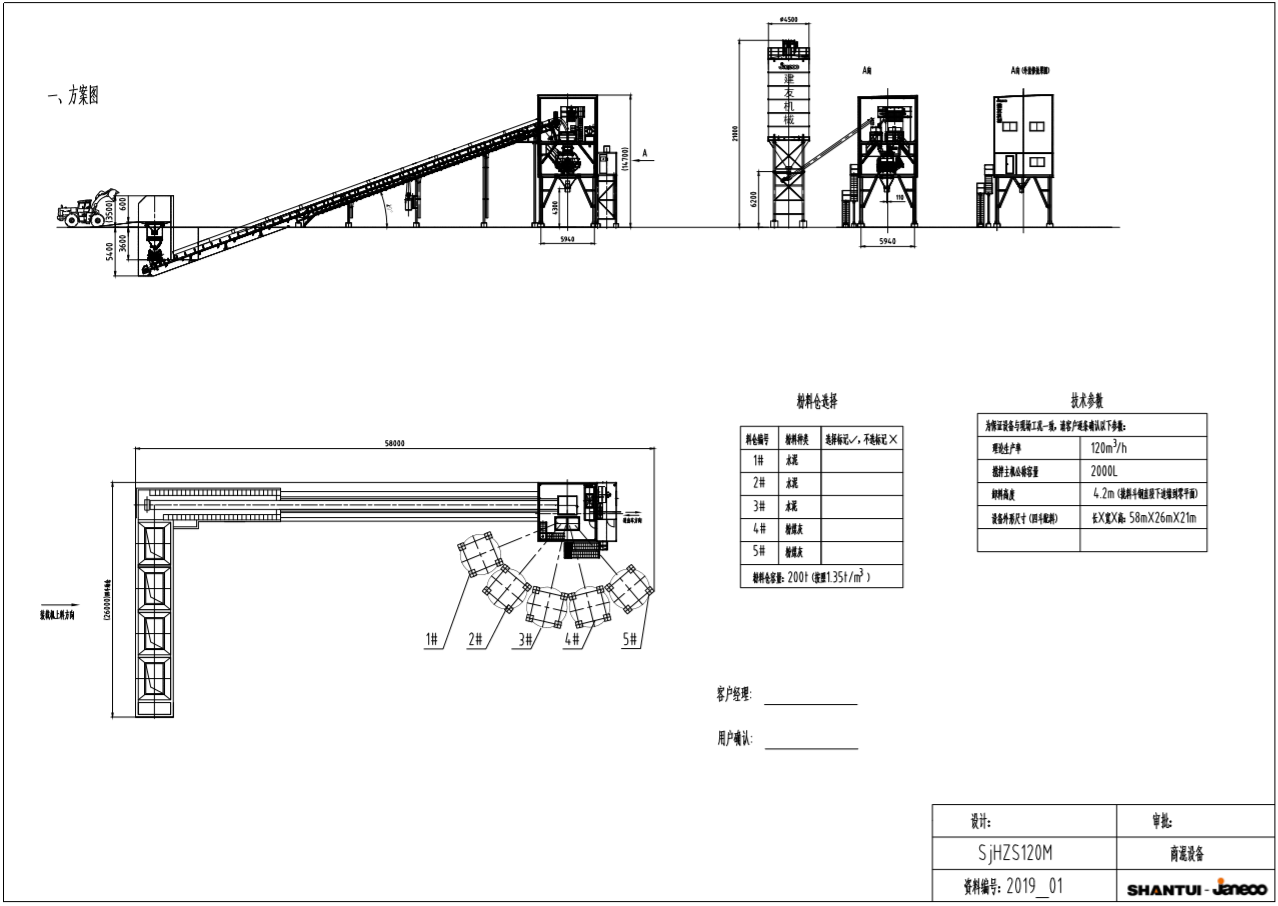

SjHZS120M configuration

|

No. |

Description |

Item |

Origin |

Qty |

Remark |

|

|

1 |

Aggregates batching system (4 hoppers ground type) |

Storage hopper |

Janeoo |

4 |

2 vibrator for 2 sand hoppers | |

| Weighing hopper(2000kg±2%) |

Janeoo |

4 |

||||

| cylinder |

SMC |

3×4 |

||||

| Sensor |

Toledo |

3×4 |

||||

| Belt machine(B:1000mm,P:5.5KW) |

Janeoo |

1 |

||||

|

2 |

Inclined belt machine |

Main support |

Janeoo |

1 |

|

|

| Driving device(P:37kW) |

Janeoo |

1 |

||||

| Belt(B:1000mm) |

Janeoo |

1 |

||||

| Water washing device |

Janeoo |

1 |

||||

|

3 |

Main building |

Main structure(2 layers platform) |

Janeoo |

1 |

|

|

| Discharging hopper |

Janeoo |

1 |

||||

| Bag type filter |

Janeoo |

1 |

||||

| Decoration |

Janeoo |

1 |

||||

|

4 |

High end mixer |

V:2.0 m3(P:2X37kW) |

Janeoo |

1 |

|

|

| Pneumatical Discharging structure |

Janeoo |

1 |

||||

| Pneumatic sealing system |

Janeoo |

1 |

||||

|

5 |

Middle hopper |

Storage hopper |

Janeoo |

1 |

|

|

| vibrator |

Janeoo |

1 |

||||

| cylinder |

SMC |

2 |

||||

|

6 |

Cement weighing system |

Weighing hopper(1000kg±1%) |

Janeoo |

1 |

|

|

| sensor |

Toledo |

3 |

||||

| Discharging valve(DN300) |

WAM |

1 |

||||

| vibrator |

Oli |

1 |

||||

|

7 |

Powder weighing system

|

Weighing hopper(400kg±1%) |

Janeoo |

1 |

|

|

| sensor |

Toledo |

3 |

||||

| Discharging valve(DN300) |

WAM |

1 |

||||

| vibrator |

Oli |

1 |

||||

|

8 |

Water weighing system |

Weighing hopper(500kg±1%) |

Janeoo |

1 |

|

|

| sensor |

Toledo |

1 |

||||

| discharging valve (DN150) |

Janeoo |

1 |

||||

| Water pump |

Janeoo |

1 |

||||

| Weighing valve(DN80) |

Janeoo |

1 |

||||

| Weighing pipes |

Janeoo |

1 |

||||

|

9 |

Additive weighing system |

Weighing hopper(50kg±1%) |

Janeoo |

1 |

Pe additive tank |

|

| sensor |

Toledo |

1 |

||||

| Discharging valve |

Janeoo |

1 |

||||

| Storage tank(V:10m3) |

Janeoo |

2 |

||||

| Additive pump |

Janeoo |

2 |

||||

| Weighing pipes |

Janeoo |

2 |

||||

|

10 |

Pneumatic system |

Air compressor(displacement:1.6 m3/min) | Atlas |

1 |

|

|

| Sotrage tank 1m3+0.3m3 |

Janeoo |

1套 |

||||

| Filter and valve |

SMC |

1 |

||||

|

11 |

Control room |

decoration |

Janeoo |

1 |

|

|

| Air conditioner |

Haier |

1 |

||||

|

12 |

Electrical system |

software |

Janeoo |

1 |

||

| Industrial computer and monitor |

Siemens |

1 |

||||

| UPS power |

Janeoo |

1 |

||||

| Printer |

OKI |

1 |

||||

| Electrical carbin and table |

Janeoo |

1 |

||||

| Main electric components |

schneider |

1 |

||||

| Monitoring system(1 monitor+4 cameras) |

Janeoo |

1 |

||||

| Optional | ||||||

|

No. |

Description |

Item |

Origin |

Qty |

Remark |

|

|

13 |

Cement silo |

200t |

Janeoo |

5 |

Cement density 1.35t/m3 |

|

| Maintenance platform |

Janeoo |

1 |

|

|||

|

14 |

Accessoies |

24㎡ filter |

Janeoo |

5 |

|

|

| Safe valve on the top |

Janeoo |

5 |

||||

| Level meter |

Janeoo |

2X5 |

||||

| Arch breaker |

Janeoo |

5 |

||||

| Manual valve |

Janeoo |

5 |

||||

|

15 |

Screw conveyor |

φ273X11m |

Janeoo |

3 |

cement |

|

| φ219X11m |

Janeoo |

2 |

powder |

|||

Product detail pictures:

Related Product Guide:

To meet the customers' over-expected pleasure , we have now our solid crew to supply our greatest all round assistance which includes marketing, sales, planning, production, top quality controlling, packing, warehousing and logistics for Reliable Supplier Concrete Mixer And Concrete Batching Plant - M series SjHZS120M specifications – Janeoo , The product will supply to all over the world, such as: Namibia, Thailand, Jeddah, When you are keen on any of our items following you view our product list, please feel free to make contact with us for inquiries. You'll be able to send us emails and get in touch with us for consultation and we shall respond to you as soon as we are able to. If it's convenient, you could find out our address in our web site and come to our enterprise. or additional information of our items by yourself. We're generally ready to build lengthy and steady co-operation relations with any possible shoppers within the associated fields.

We have worked with many companies, but this time is the best,detailed explanation, timely delivery and quality qualified, nice!