Online Exporter Cement Mixing Plant Price - Road base Material Mixing Plant – Janeoo

Online Exporter Cement Mixing Plant Price - Road base Material Mixing Plant – Janeoo Detail:

Product Feature:

1.Concrete mixer adopts lining-plate-free mixing technology, so as to avoid wearing to the mixing blade and lining plate once and for all, making it easy for maintenance.

2.All materials are weighed up in electronic scale, which is controlled by variable frequency converter, featuring high weighing accuracy.

3.Adopting advanced centralized aggregate batching control system, so that batching accuracy and work efficiency of the whole plant can both be improved.

4.Modular structure, easy installation and rapid plant transfer.

5.Product purpose: Adapts to roadbed material pavement of all-grade roads, urban road, playground, wharf, etc.

Technical parameters

| Model | SjWBZ300 | SjWBZ400 | SjWBZ500 | SjWBZ600 | SjWBZ700 | SjWBZ800 | |

| Rated capacity(t/h) | 300 | 400 | 500 | 600 | 700 | 800 | |

|

Mixer |

Mixer rate power(kW) | 2X22 | 2X22 | 2X30 | 2X37 | 2X37 | 2X45 |

| Aggregate size(mm) | ≤50 | ≤50 | ≤50 | ≤50 | ≤50 | ≤50 | |

| Aggregate Bin Capacity (m³) | 4X12 | 4X12 | 4X12 | 5X12 | 5X12 | 5X15 | |

| Belt conveyance (t/h) | 300 | 400 | 500 | 600 | 700 | 800 | |

|

Weighing accuracy |

Aggregate | ±2% | ±2% | ±2% | ±2% | ±2% | ±2% |

| Cement | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | |

| Water | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | |

| Total power(kW) | 125 | 125 | 149 | 166 | 166 | 198 | |

| Discharge height(m) | 3.6 | 3.6 | 3.6 | 3.6 | 3.6 | 3.6 | |

All specification is subject to modification.

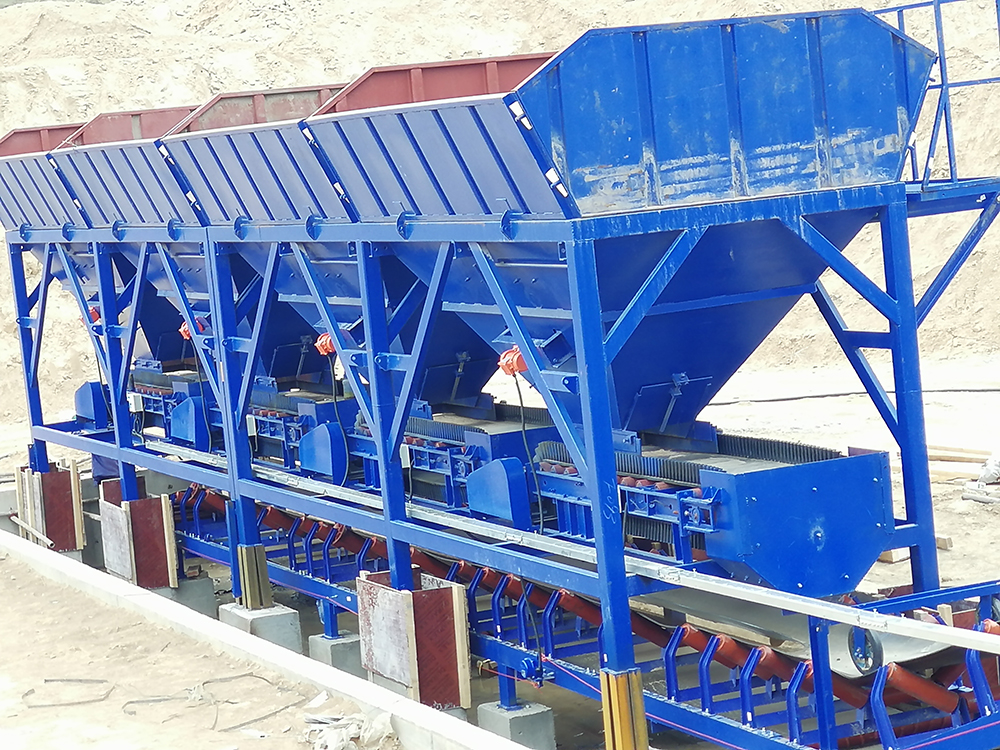

Product Components

Product detail pictures:

Related Product Guide:

Innovation, excellent and reliability are the core values of our company. These principles today much more than ever form the basis of our success as an internationally active mid-size business for Online Exporter Cement Mixing Plant Price - Road base Material Mixing Plant – Janeoo , The product will supply to all over the world, such as: Guatemala, New York, Jordan, We always adhere to follow the honesty, mutual benefit, common development, after years of development and the tireless efforts of all staff, now has perfect export system, diversified logistics solutions, comprehensive meet customer shipping, air transport, international express and logistics services. Elaborate one-stop sourcing platform for our customers!

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.