OEM/ODM Factory Mixing Machine Concrete Batching Plant Hzs50 - Road base Material Mixing Plant – Janeoo

OEM/ODM Factory Mixing Machine Concrete Batching Plant Hzs50 - Road base Material Mixing Plant – Janeoo Detail:

Product Feature:

1.Concrete mixer adopts lining-plate-free mixing technology, so as to avoid wearing to the mixing blade and lining plate once and for all, making it easy for maintenance.

2.All materials are weighed up in electronic scale, which is controlled by variable frequency converter, featuring high weighing accuracy.

3.Adopting advanced centralized aggregate batching control system, so that batching accuracy and work efficiency of the whole plant can both be improved.

4.Modular structure, easy installation and rapid plant transfer.

5.Product purpose: Adapts to roadbed material pavement of all-grade roads, urban road, playground, wharf, etc.

Technical parameters

| Model | SjWBZ300 | SjWBZ400 | SjWBZ500 | SjWBZ600 | SjWBZ700 | SjWBZ800 | |

| Rated capacity(t/h) | 300 | 400 | 500 | 600 | 700 | 800 | |

|

Mixer |

Mixer rate power(kW) | 2X22 | 2X22 | 2X30 | 2X37 | 2X37 | 2X45 |

| Aggregate size(mm) | ≤50 | ≤50 | ≤50 | ≤50 | ≤50 | ≤50 | |

| Aggregate Bin Capacity (m³) | 4X12 | 4X12 | 4X12 | 5X12 | 5X12 | 5X15 | |

| Belt conveyance (t/h) | 300 | 400 | 500 | 600 | 700 | 800 | |

|

Weighing accuracy |

Aggregate | ±2% | ±2% | ±2% | ±2% | ±2% | ±2% |

| Cement | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | |

| Water | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | |

| Total power(kW) | 125 | 125 | 149 | 166 | 166 | 198 | |

| Discharge height(m) | 3.6 | 3.6 | 3.6 | 3.6 | 3.6 | 3.6 | |

All specification is subject to modification.

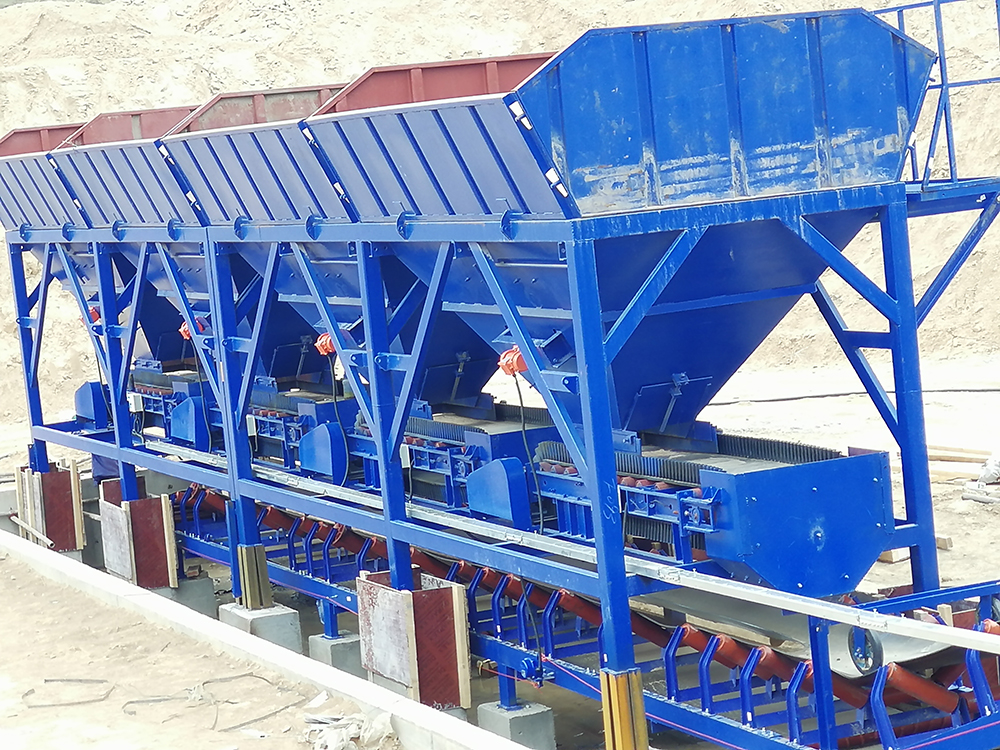

Product Components

Product detail pictures:

Related Product Guide:

Sticking for the principle of "Super Quality, Satisfactory service" ,We have been striving for being a superb small business partner of you for OEM/ODM Factory Mixing Machine Concrete Batching Plant Hzs50 - Road base Material Mixing Plant – Janeoo , The product will supply to all over the world, such as: British, Czech republic, Riyadh, It using the world's leading system for reliable operation, a low failure rate, it suitable for Argentina customers choice. Our company is situated within the national civilized cities, the traffic is very convenient, unique geographical and economic conditions. We pursue a people-oriented, meticulous manufacturing, brainstorm, build brilliant" business philosophy. Strict quality management, perfect service, reasonable price in Argentina is our stand on the premise of competition. If necessary, welcome to contact us by our website or phone consultation, we will be happy to serve you.

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!