OEM Supply Thailand Concrete Batching Plant Supplier - SjHZS180G G series enviroment friendly type – Janeoo

OEM Supply Thailand Concrete Batching Plant Supplier - SjHZS180G G series enviroment friendly type – Janeoo Detail:

SjHZS180G advantages

1. Characteristics:

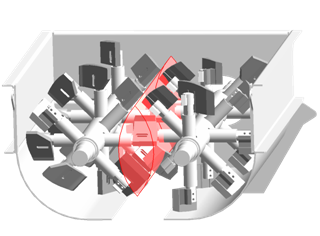

1.1. Double-axis and four-screw efficient mixing host;

1.2. multi-point monitoring, real-time monitoring of

the quality of concrete.

1.3. The actual production efficiency of 160m3/h

is much higher than the industry average

130m3/h efficiency.

Application: It is adapted to ready-mix concrete production.

Description:

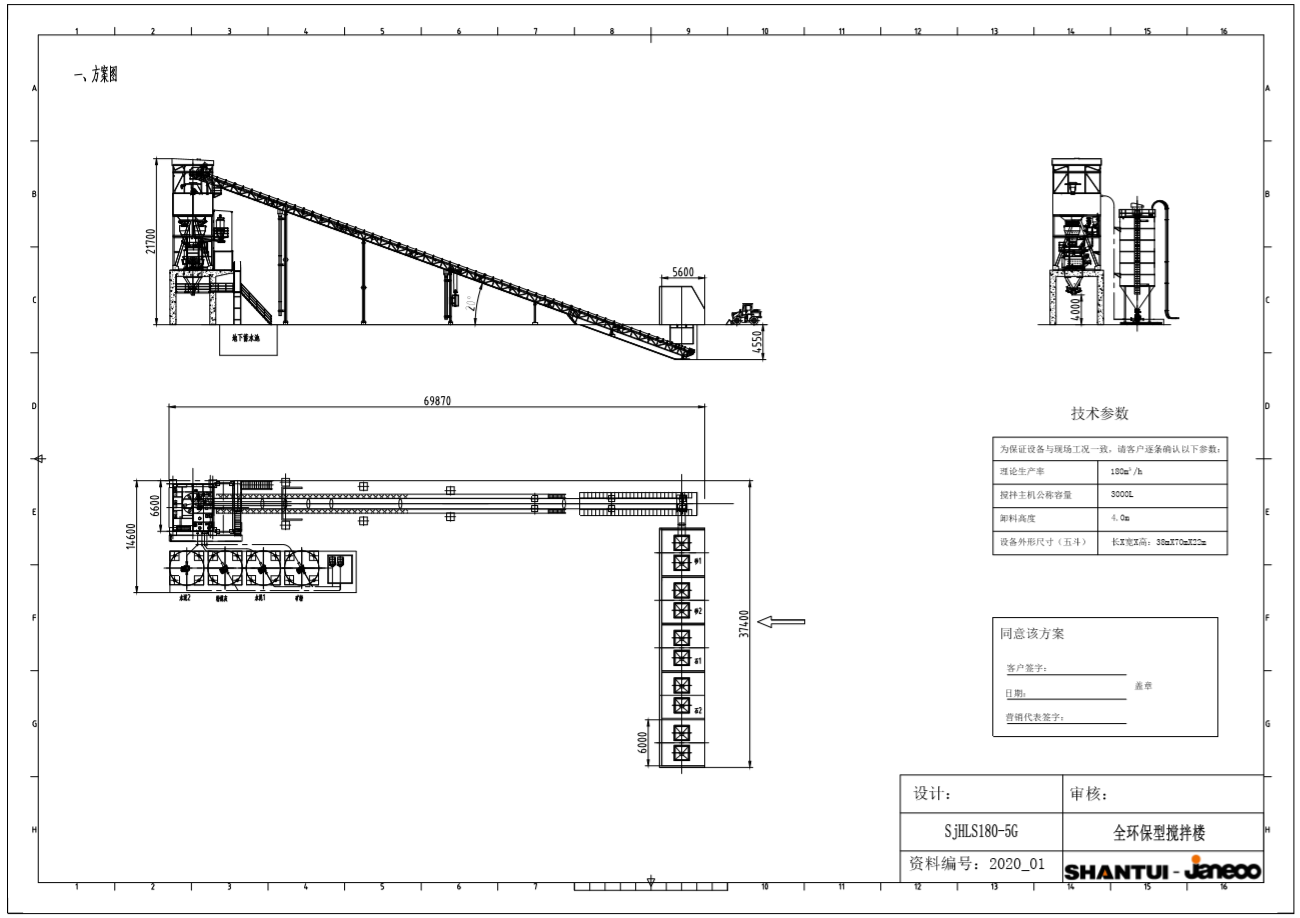

SjHZS180-5G Concrete mixing plant adopts modular structure, which has the characteristics of high efficiency, energy saving and environmental protection.

1.1 Modular design

In this equipment, modularization has been realized, which can be divided into units for transportation and hoisted and combined for installation, which is simple and fast.It can shorten the installation time, improve economic benefit, and can be arranged flexibly according to different installation

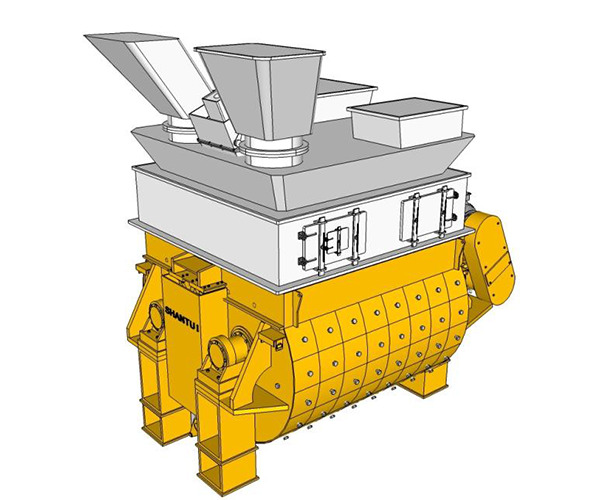

2.1 SjJS3000G mixer with high strength, high flow and explosive power

2.2 Unique cutting effect:

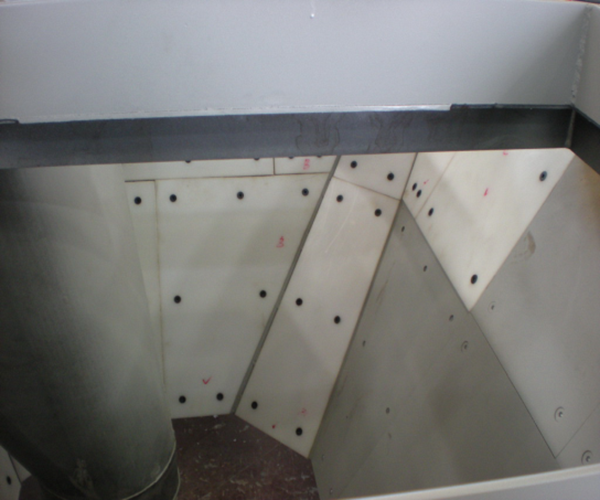

2.3 Unique air sealing device

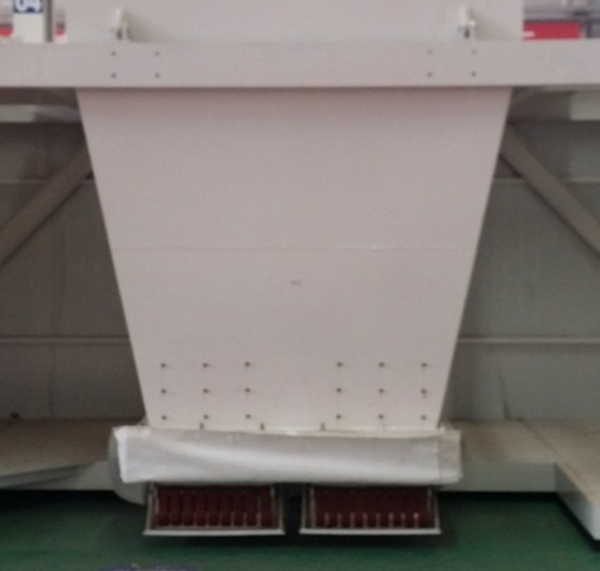

3.1Unique 6m large-capacity finished product hopper:

4.1 Each weighing system has fine adjustment and compensation device, high weighing precision

5,Ready-mix feeding device

Construction cases:

Configuration

| 1、Main configuration | |||||

|

Description |

Item |

Specification |

Qty |

Unit |

Origin |

|

1 Aggregates batching machine (ground type) |

Sand hoppers(ground type) | 50 m3 |

2 |

set |

Sensor:TOLEDO;Parts:SMC;

Accuracy:±2%; |

| Stone hoppers(ground type) | 50 m3 |

2 |

set |

||

| Weighing system | Max 3000kg |

4 |

set |

||

| Sensor | SBT-2 |

12 |

Pc. |

||

| Discharging gate |

4 |

set |

|||

| Flat conveying system | 400m3/h,B=1000mm |

1 |

set |

||

| Driving system |

1 |

set |

|||

| Belt machine structure |

1 |

set |

|||

| Security device |

1 |

set |

|||

|

2 Aggregates conveying system |

Inclined conveying system | 400m3/h ,B=1000mm |

1 |

set |

|

| Driving system |

1 |

set |

|||

| Belt machine structure |

1 |

set |

|||

| Whole Seal decoration |

1 |

set |

|||

| Security device |

1 |

set |

|||

| Chute washing device |

1 |

set |

|||

| Clean device |

1 |

set |

|||

|

3 Main building |

Main steel structure | Discharging height 4m |

1 |

set |

Parts: SMC;

Filter:WAM; |

| Main Filter |

44 m2 |

1 |

set |

||

| Belt filter |

6 m2 |

1 |

set |

||

| Main decoration |

(50mm) |

1 |

set |

||

| Concrete hopper | V:6 m3 |

1 |

set |

||

| Monitoring device |

1 |

set |

|||

| Vibrator | MVE200-3 |

1 |

set |

||

| Maintenance platform |

1 |

set |

|||

| Middle storage hopper |

1 |

set |

|||

| Weighing sensor | SBT-3 |

1 |

Pc. |

||

| vibrator | MVE200-3 |

1 |

set |

||

| Mixer | JS3000G(V:3 m3) |

1 |

Pc. |

||

| Driving system | 2×55kW |

2 |

set |

||

| Cylinder | CB-140B-450 |

2 |

Pc. |

||

| Feeding device |

1 |

set |

|||

| Water pump |

1 |

set |

|||

| Monitoring device |

1 |

set |

|||

| Cement weighing system | Max 1800kg |

1 |

Pc. |

Sensor:TOLEDO;Valve:WAM;

Accuracy:±1%; |

|

| Weighing sensor | SBT-2 |

3 |

Pc. |

||

| Valve | V1FS250 |

1 |

Pc. |

||

| Vibrator |

S30 |

1 |

Pc. |

||

| Powder weighing system | Max 900kg |

1 |

Pc. |

||

| Weighing sensor | SBT-2 |

3 |

Pc. |

||

| Valve | V1FS250 |

1 |

Pc. |

||

| Vibrator |

S30 |

1 |

Pc. |

||

| Mine weighing system | Max 500kg |

1 |

Pc. |

||

| Weighing sensor | SBT-2 |

3 |

Pc. |

||

| Valve | V1FS250 |

1 |

Pc. |

||

| Vibrator |

S30 |

1 |

Pc. |

||

| Water weighing system | Max 800kg |

1 |

Pc. |

Sensor:TOLEDO;Accuracy:±1%; | |

| Weighing sensor | TSC-1000 |

3 |

Pc. |

||

| Valve |

1 |

Pc. |

|||

| Additive weighing system | Max 100kg |

1 |

Pc. |

(Patent item)Sensor:TOLEDO;

Accuracy:±1% |

|

| Sensor | TSC-300 |

1 |

Pc. |

||

| Valve |

1 |

Pc. |

|||

| Anti leaking device |

1 |

set |

|||

|

4 Water supply system |

Valve |

Each 1 |

set |

||

| Pipes(Inter) |

1 |

set |

|||

| Water pump |

1 |

Pc. |

|||

| Pool and pipes(outer) | By customer |

1 |

set |

||

|

5 Liquid additive system |

Pipes |

Each 1 |

set |

||

| Pipes(Inter) |

2 |

set |

|||

| Additive tank and pipes(outer) | With pump,10T iron tank |

2 |

set |

||

|

6 Pneumatic system |

Air compressor | 15kW |

1 |

Pc. |

Parts:SMC;Dryer:SMC; |

| Storage tank | 1m3 +0.3m3 |

1 |

set |

||

| Dryer |

1 |

set |

|||

| Pipe |

1 |

set |

|||

| Parts |

1 |

set |

|||

|

7 Control system |

Control room |

1 |

set |

Main components:schneider;

PLC:Siemens ; Monitor:SAMSUNG;

|

|

| Software | Bosure |

1 |

set |

||

| Operating table |

1 |

set |

|||

| Control table |

1 |

set |

|||

| Monitor | 22” |

1 |

Pc. |

||

| Printer | EPSON |

1 |

Pc. |

||

| Air conditioner | 1.5 |

1 |

Pc. |

||

| Computer |

1 |

Pc. |

|||

| Monitoring system | 4 cameras |

1 |

set |

||

| Monitor | 22” |

1 |

set |

||

| Light system |

1 |

set |

|||

| Communication | 4 cameras |

1 |

set |

||

| 2、Optional | |||||

|

1 Cement silo |

SC300 | V:300T(V:225m3,cement) |

5 |

set |

Cement 3set、powder 1set、mine powder 1set |

| SC100 | V:100T(V:73m3,cement) |

1 |

set |

Swelling additive | |

| Accessories | Filter, level meter, arch breaker etc… |

6 |

set |

Filter:Pulse back flush typeValve:WAM。 | |

| Platform on the top |

|

1 |

set | Connection of all silos | |

|

2 Screw conveyor |

For cement | φ323 |

3 |

set |

WAM |

| For powder | φ273 |

1 |

set |

WAM | |

| For mine powder | φ219 |

2 |

set |

WAM | |

Product detail pictures:

Related Product Guide:

Our commission would be to serve our customers and clientele with very best excellent and aggressive portable digital products for OEM Supply Thailand Concrete Batching Plant Supplier - SjHZS180G G series enviroment friendly type – Janeoo , The product will supply to all over the world, such as: Chile, Curacao, Atlanta, With excellent products, high quality service and sincere attitude of service, we ensure customer satisfaction and help customers create value for mutual benefit and create a win-win situation. Welcome customers all over the world to contact us or visit our company. We will satisfy you with our professional service!

This supplier offers high quality but low price products, it is really a nice manufacturer and business partner.