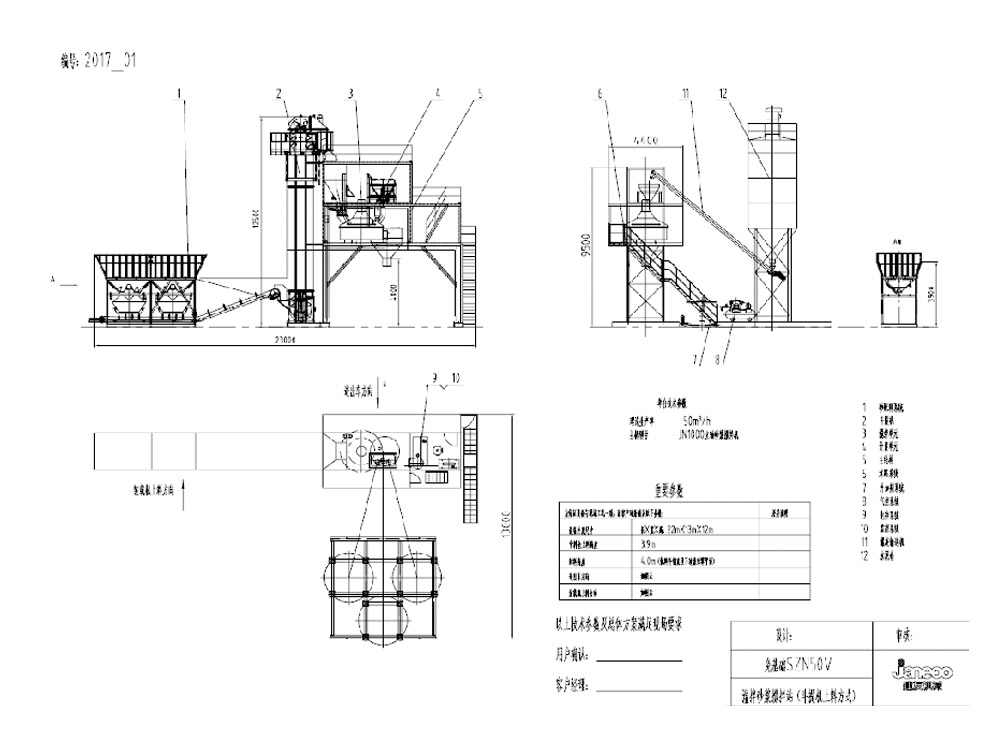

Manufacturer for Automatic Concrete Batching Plant - Asphalt batching plant SjLBZ160/180-5B – Janeoo

Manufacturer for Automatic Concrete Batching Plant - Asphalt batching plant SjLBZ160/180-5B – Janeoo Detail:

Features of Asphalt Plant

-Our asphalt mixing plants are designed in modular structure.

-Вy adopting “inertial + back-blowing” type bag flter, our asphalt mixing plant is highly eco-friendly.

-The burner of our plant is compatible with any kinds of fuel.

-The vibration and screening technology aсquired from Germany offers us a 4- 6-class aggregate screening.

-Side-installed or underneath-type finished-product storage hoppers are provided for your option.

Main Components

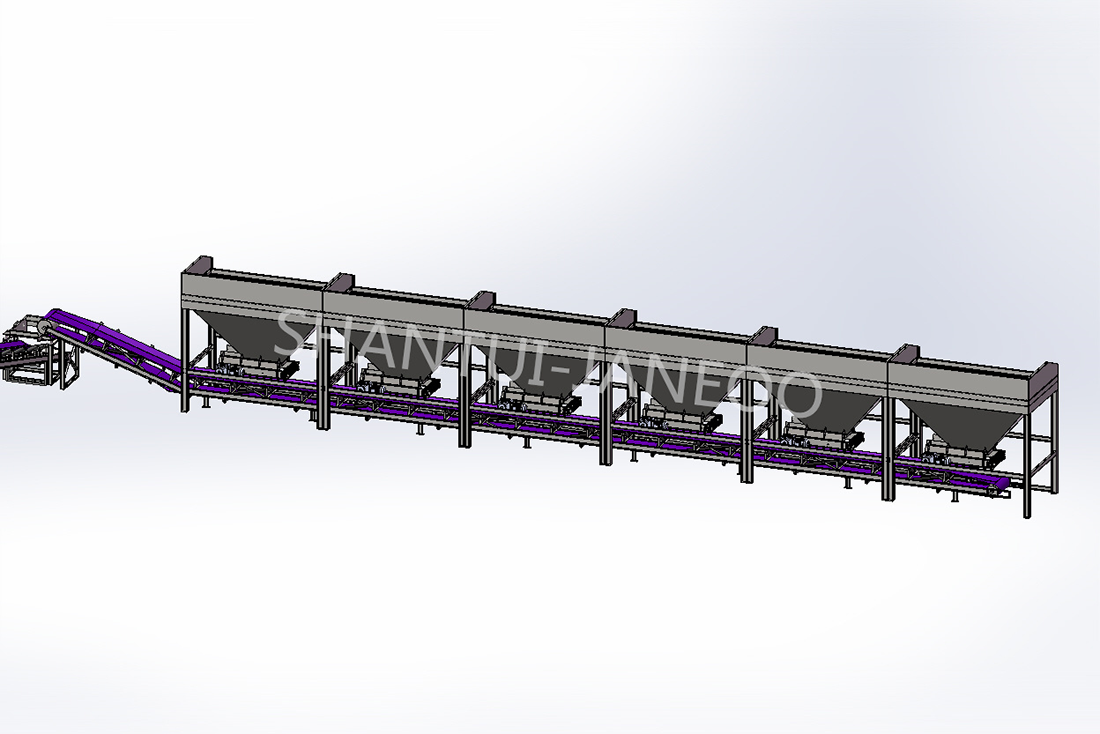

1 Cold Aggregate Bin

Use Frequency Control which have wide regulation range and very steady running Audible

material supply Use famous brand vibrator and frequency convertor Convenient assembly and low failure Every bin

have isolation screen avoid big size material enter

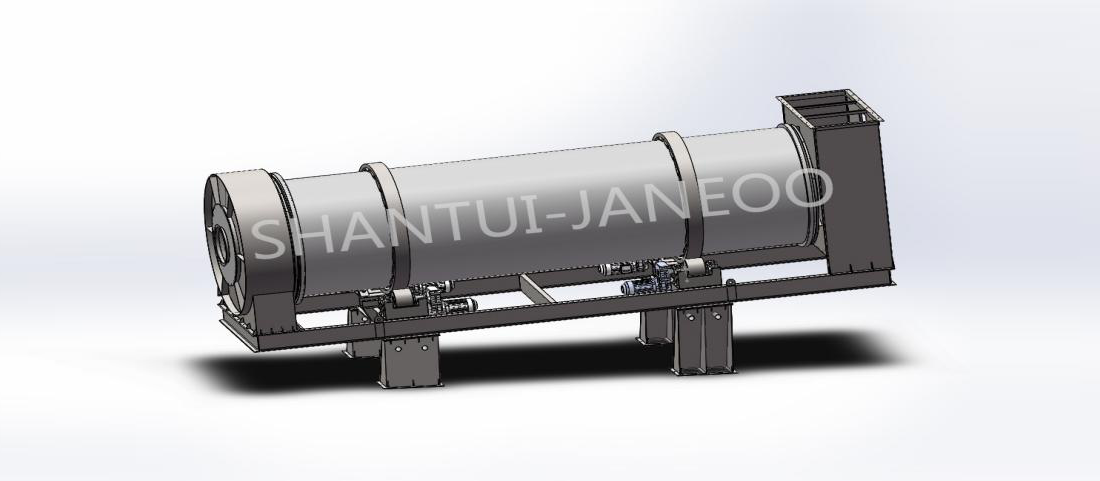

2 Drying system

Use brand reducer which can guarantee reliability.

Optimized lifting board arrangement improve thermal efficiency.

Covered mineral wool layer reduce the heat loss.

3 Burner

have different fuel burner for customer to choose like heavy oil, diesel oil, coal, gas ,gas and oil burner, also have different brandburner :like Italy brand,Canada, and china brand burner for customer to choose. The burner have high reliability and easy to operate and maintenance.

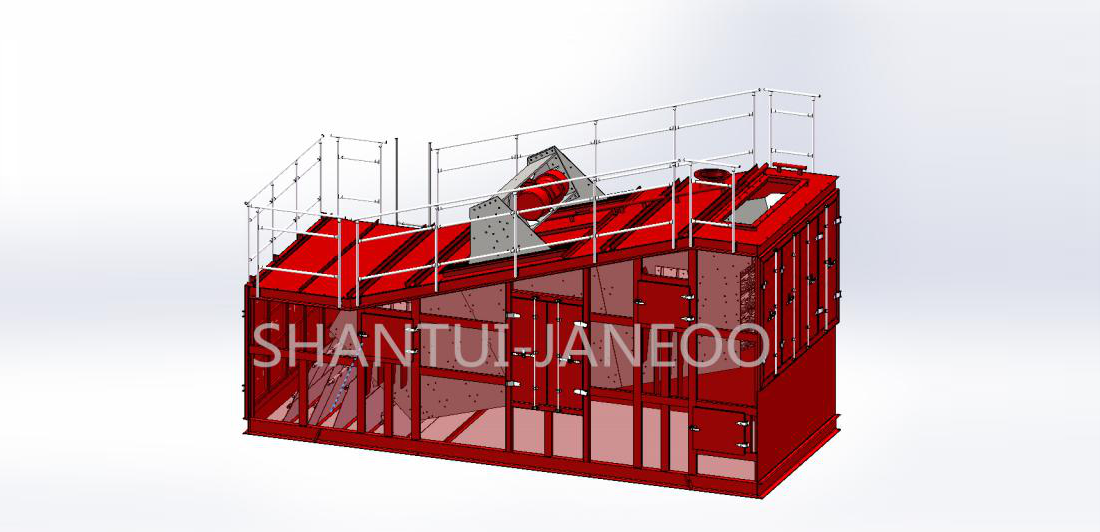

4 Vibration screen

Fully enclosed design which can avoid dust out. Screen use high-strength manganese steel material, easy to replace the screen.

5 Hot Aggregate bin

The enlarged hot bins make sure the production Continuity, enhance the production capacity

The hot bin is covered with mineral wool which makes sure the heat preserve function

6 Weighing sensor

Use American famous brand weighing sensor make sure the weighing precision ,the sensor can adjust to any bad weather condition

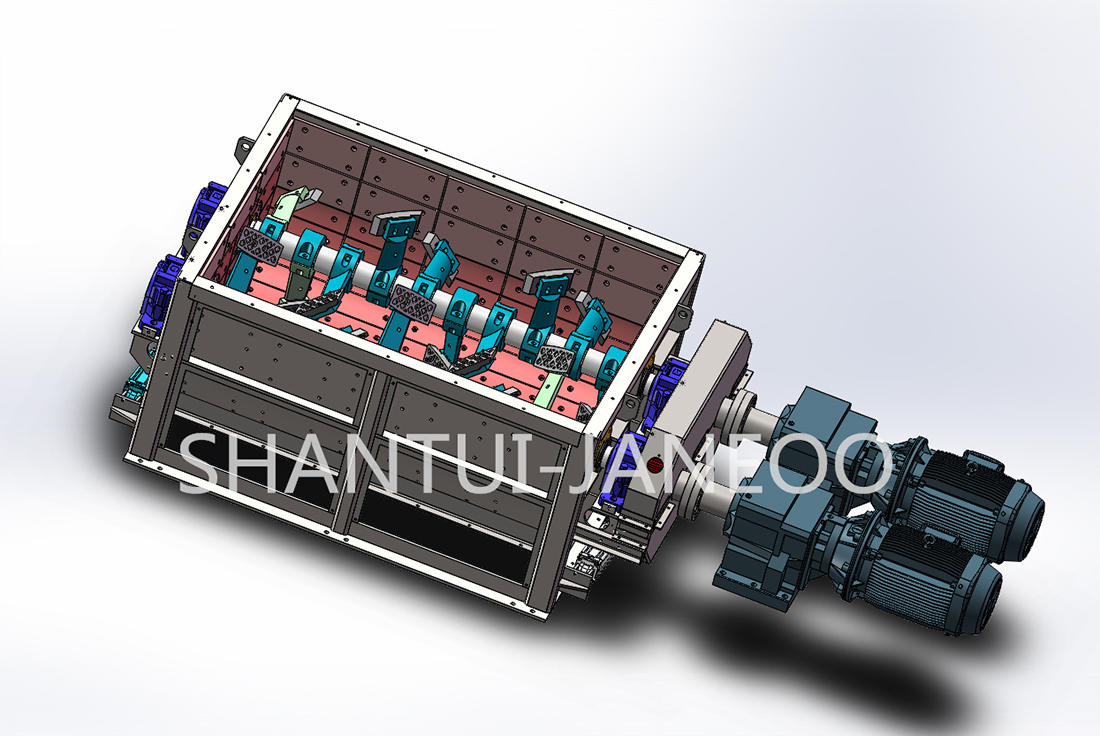

7 Mixing system

High-strength wear-resistant lining board and blade chrome alloy castings, to ensure its effective life.

Enlarged mixing tank guarantee the mixing efficiency and enhance the production capacity.

Our mixing tank capacity is about 20%-30% large than standard mixing tank.

8 Bitumen supply ,storage and heating system

Big capacity bitumen tank

Use in-direct type hot oil heater which have high heating performance and

reliability, the hot oil heater use Italy brand burner who have very good performance

Use integrated type asphalt tank, it is easy to assembly and transport

9 Dust collector

Primary dust collector use volute or drum type dust collector according to secondary dust collector type. It can guarantee dust collecting

performance

The volute dust collector have regulation gate which can regulate the collected dust diameter and volume.

Secondary dust collector use water dust collector or bag dust collector for customer to choose according to worksite condition

10 Electric control system

Use international famous brand air compressor and pneumatic control parts ,with high reliability and lower failure rate.

Computer automatic control ,use Siemens latest performance PLC controller , high automation and reliability.

Main electrical parts use international brand like Siemens, Schneider or Omron ,it can make long time performance life.

The computer have the automatic failure and Diagnostic function, if there is any failure ,will have automatic display

Technical parameters

|

Model |

SjLBZ160-5B |

|

| Theoretic productivity(t/h) | 160 | |

| Mixer capacity(kg) | 2000 | |

| Weighing range ang measurement accuracy | Aggregate | 2000±0.5% |

| Powder | 300±0.3% | |

| Asphalt | 200±0.2% | |

| Total power(kW) | 400 | |

| Fuel consumption(kg/t) | ≤6.5 | |

Product detail pictures:

Related Product Guide:

owing to good service, a variety of high quality products, competitive prices and efficient delivery, we enjoy a good reputation among our customers. We are an energetic company with wide market for Manufacturer for Automatic Concrete Batching Plant - Asphalt batching plant SjLBZ160/180-5B – Janeoo , The product will supply to all over the world, such as: Florida, Slovenia, Venezuela, Our solutions are widely recognized and trusted by users and can meet continuously changing of economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!