Factory wholesale Medium Sized Concrete Batching Plant - High-speed railway dedicated concrete batching plant – Janeoo

Factory wholesale Medium Sized Concrete Batching Plant - High-speed railway dedicated concrete batching plant – Janeoo Detail:

Features

1.Modular design, convenient to assemble and disassemble, fast transfer, flexible layout;

2.Adopting high-efficiency mixer,high production efficiency, supporting multiple types fo feeding technology, suitable for various concrete mixing needs, the lining boards and blades adopt alloy wear-resistant material, with long service life.

3.The aggregate measurement system achieves high-precision measurement of aggregate by optimizing the discharge door structure, improving the vibration form of the vibrator, and increasing the closing speed of the discharge door;

4. Powder measurement By installing a precise measurement screw in the lower part of the main spiral, a coarse and fine powder scale can be realized;

5. There is a liquid storage bag on the top of the water/additive weighing scale so that it realizes the coarse-fine measurement.

6. With Siemens industrial control computer as the platform, the production control software adopts the most advanced automatic scale compensation and deduction scale technology in China to ensure that the measurement accuracy of various raw materials meets the technical requirements of high-speed railway construction;

7. Fully-sealed arc discharging gate of the aggregate storage bin to meet the high-speed railway secondary material feeding and mixing process.

Specification

|

Mode |

SjHZS090R |

SjHZS120R |

SjHZS180R |

SjHZS240R |

SjHZS270R |

|||

| Theoretical productivity m³/h | 90 | 120 | 180 | 240 | 270 | |||

| Mixer | Mode | JS1500 | JS2000 | JS3000 | JS4000 | JS4500 | ||

| Driving power(Kw) | 2X30 | 2X37 | 2X55 | 2X75 | 2X75 | |||

| Discharging capacity(L) | 1500 | 2000 | 3000 | 4000 | 4500 | |||

| Max. aggregate sizeGravel/Pebble mm) | ≤60/80 | ≤60/80 | ≤60/80 | ≤60/80 | ≤60/80 | |||

| Batching bin | Volume m³ | 4X12 | 4X20 | 4X20 | 4X30 | 4X30 | ||

| Belt conveyor capacity t/h | 300 | 400 | 600 | 800 | 800 | |||

| Weighing range and measurement accuracy | Aggregate kg | 4X(1500±2%) | 4X(2000±2%) | 4X(3000±2%) | 4X(4000±2%) | 4X(4500±2%) | ||

| Cement kg | 800±1% | 1000±1% | 1500±1% | 2000±1% | 2500±1% | |||

| Flyash kg | 200±1% | 400±1% | 600±1% | 800±1% | 900±1% | |||

| Ore powder kg | 200±1% | 300±1% | 400±1% | 500±1% | 600±1% | |||

| Water kg | 300±1% | 400±1% | 600±1% | 800±1% | 900±1% | |||

| Additive kg | 30±1% | 40±1% | 60±1% | 80±1% | 90±1% | |||

| Discharging height m | 4.2 | 4.2 | 4.2 | 4.2 | 4.2 | |||

| Total power | 150 | 200 | 250 | 300 | 300 | |||

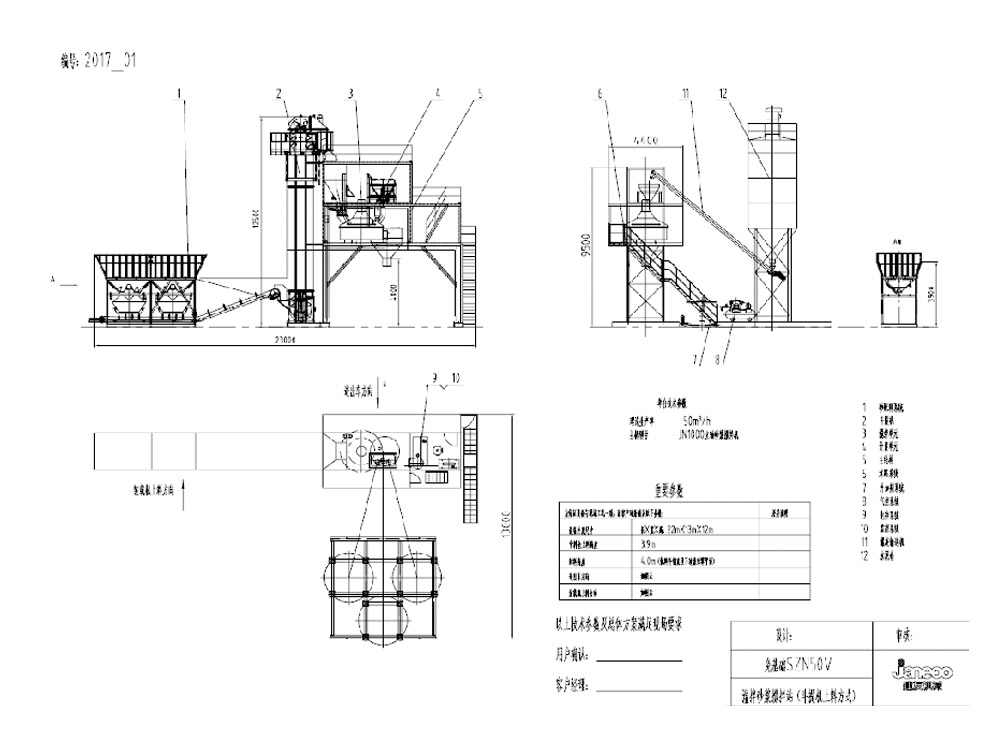

Product detail pictures:

Related Product Guide:

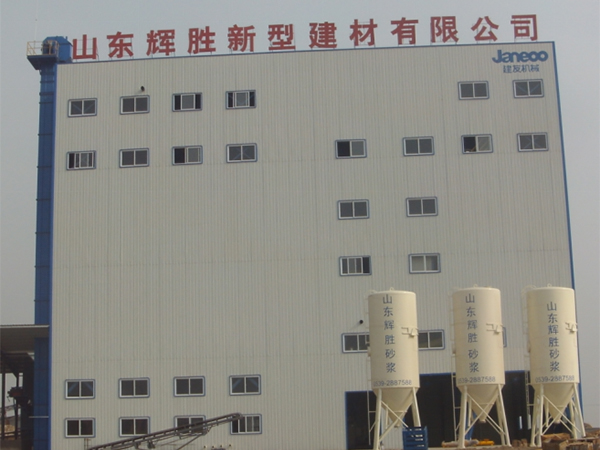

Our target is always to satisfy our customers by offering golden support, superior value and high quality for Factory wholesale Medium Sized Concrete Batching Plant - High-speed railway dedicated concrete batching plant – Janeoo , The product will supply to all over the world, such as: Argentina, Denmark, kazan, We've got constructed strong and long co-operation relationship with an enormous quantity of companies within this business in Kenya and overseas. Immediate and professional after-sale service supplied by our consultant group has happy our buyers. Thorough Info and parameters from the merchandise will probably be sent for you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Kenya for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

A good manufacturers, we have cooperated twice, good quality and good service attitude.