factory Outlets for Concrete Batching Plant In Australia - M series SjHZS120M specifications – Janeoo

factory Outlets for Concrete Batching Plant In Australia - M series SjHZS120M specifications – Janeoo Detail:

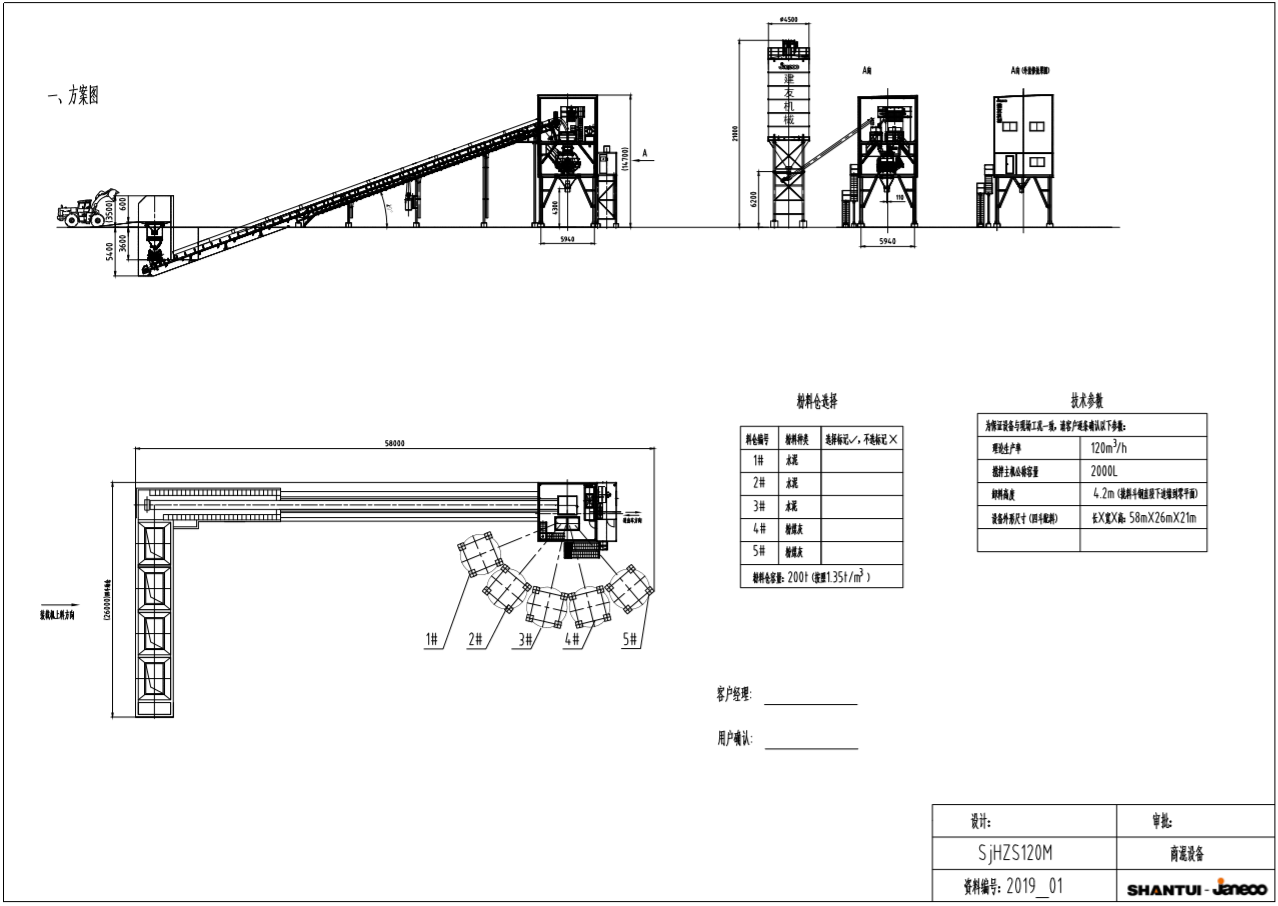

SjHZS120M configuration

|

No. |

Description |

Item |

Origin |

Qty |

Remark |

|

|

1 |

Aggregates batching system (4 hoppers ground type) |

Storage hopper |

Janeoo |

4 |

2 vibrator for 2 sand hoppers | |

| Weighing hopper(2000kg±2%) |

Janeoo |

4 |

||||

| cylinder |

SMC |

3×4 |

||||

| Sensor |

Toledo |

3×4 |

||||

| Belt machine(B:1000mm,P:5.5KW) |

Janeoo |

1 |

||||

|

2 |

Inclined belt machine |

Main support |

Janeoo |

1 |

|

|

| Driving device(P:37kW) |

Janeoo |

1 |

||||

| Belt(B:1000mm) |

Janeoo |

1 |

||||

| Water washing device |

Janeoo |

1 |

||||

|

3 |

Main building |

Main structure(2 layers platform) |

Janeoo |

1 |

|

|

| Discharging hopper |

Janeoo |

1 |

||||

| Bag type filter |

Janeoo |

1 |

||||

| Decoration |

Janeoo |

1 |

||||

|

4 |

High end mixer |

V:2.0 m3(P:2X37kW) |

Janeoo |

1 |

|

|

| Pneumatical Discharging structure |

Janeoo |

1 |

||||

| Pneumatic sealing system |

Janeoo |

1 |

||||

|

5 |

Middle hopper |

Storage hopper |

Janeoo |

1 |

|

|

| vibrator |

Janeoo |

1 |

||||

| cylinder |

SMC |

2 |

||||

|

6 |

Cement weighing system |

Weighing hopper(1000kg±1%) |

Janeoo |

1 |

|

|

| sensor |

Toledo |

3 |

||||

| Discharging valve(DN300) |

WAM |

1 |

||||

| vibrator |

Oli |

1 |

||||

|

7 |

Powder weighing system

|

Weighing hopper(400kg±1%) |

Janeoo |

1 |

|

|

| sensor |

Toledo |

3 |

||||

| Discharging valve(DN300) |

WAM |

1 |

||||

| vibrator |

Oli |

1 |

||||

|

8 |

Water weighing system |

Weighing hopper(500kg±1%) |

Janeoo |

1 |

|

|

| sensor |

Toledo |

1 |

||||

| discharging valve (DN150) |

Janeoo |

1 |

||||

| Water pump |

Janeoo |

1 |

||||

| Weighing valve(DN80) |

Janeoo |

1 |

||||

| Weighing pipes |

Janeoo |

1 |

||||

|

9 |

Additive weighing system |

Weighing hopper(50kg±1%) |

Janeoo |

1 |

Pe additive tank |

|

| sensor |

Toledo |

1 |

||||

| Discharging valve |

Janeoo |

1 |

||||

| Storage tank(V:10m3) |

Janeoo |

2 |

||||

| Additive pump |

Janeoo |

2 |

||||

| Weighing pipes |

Janeoo |

2 |

||||

|

10 |

Pneumatic system |

Air compressor(displacement:1.6 m3/min) | Atlas |

1 |

|

|

| Sotrage tank 1m3+0.3m3 |

Janeoo |

1套 |

||||

| Filter and valve |

SMC |

1 |

||||

|

11 |

Control room |

decoration |

Janeoo |

1 |

|

|

| Air conditioner |

Haier |

1 |

||||

|

12 |

Electrical system |

software |

Janeoo |

1 |

||

| Industrial computer and monitor |

Siemens |

1 |

||||

| UPS power |

Janeoo |

1 |

||||

| Printer |

OKI |

1 |

||||

| Electrical carbin and table |

Janeoo |

1 |

||||

| Main electric components |

schneider |

1 |

||||

| Monitoring system(1 monitor+4 cameras) |

Janeoo |

1 |

||||

| Optional | ||||||

|

No. |

Description |

Item |

Origin |

Qty |

Remark |

|

|

13 |

Cement silo |

200t |

Janeoo |

5 |

Cement density 1.35t/m3 |

|

| Maintenance platform |

Janeoo |

1 |

|

|||

|

14 |

Accessoies |

24㎡ filter |

Janeoo |

5 |

|

|

| Safe valve on the top |

Janeoo |

5 |

||||

| Level meter |

Janeoo |

2X5 |

||||

| Arch breaker |

Janeoo |

5 |

||||

| Manual valve |

Janeoo |

5 |

||||

|

15 |

Screw conveyor |

φ273X11m |

Janeoo |

3 |

cement |

|

| φ219X11m |

Janeoo |

2 |

powder |

|||

Product detail pictures:

Related Product Guide:

Our primary purpose is to give our shoppers a serious and responsible company relationship, giving personalized attention to all of them for factory Outlets for Concrete Batching Plant In Australia - M series SjHZS120M specifications – Janeoo , The product will supply to all over the world, such as: South Africa, Honduras, Poland, During the development, our company has built a well-known brand. It is well highly acclaimed by our customers. OEM and ODM are accepted. We are looking forward to customers from all over the world to join us to a wild cooperation.

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.