China Supplier 50m3/H Mini Concrete Batching Plant - M series SjHZS120M specifications – Janeoo

China Supplier 50m3/H Mini Concrete Batching Plant - M series SjHZS120M specifications – Janeoo Detail:

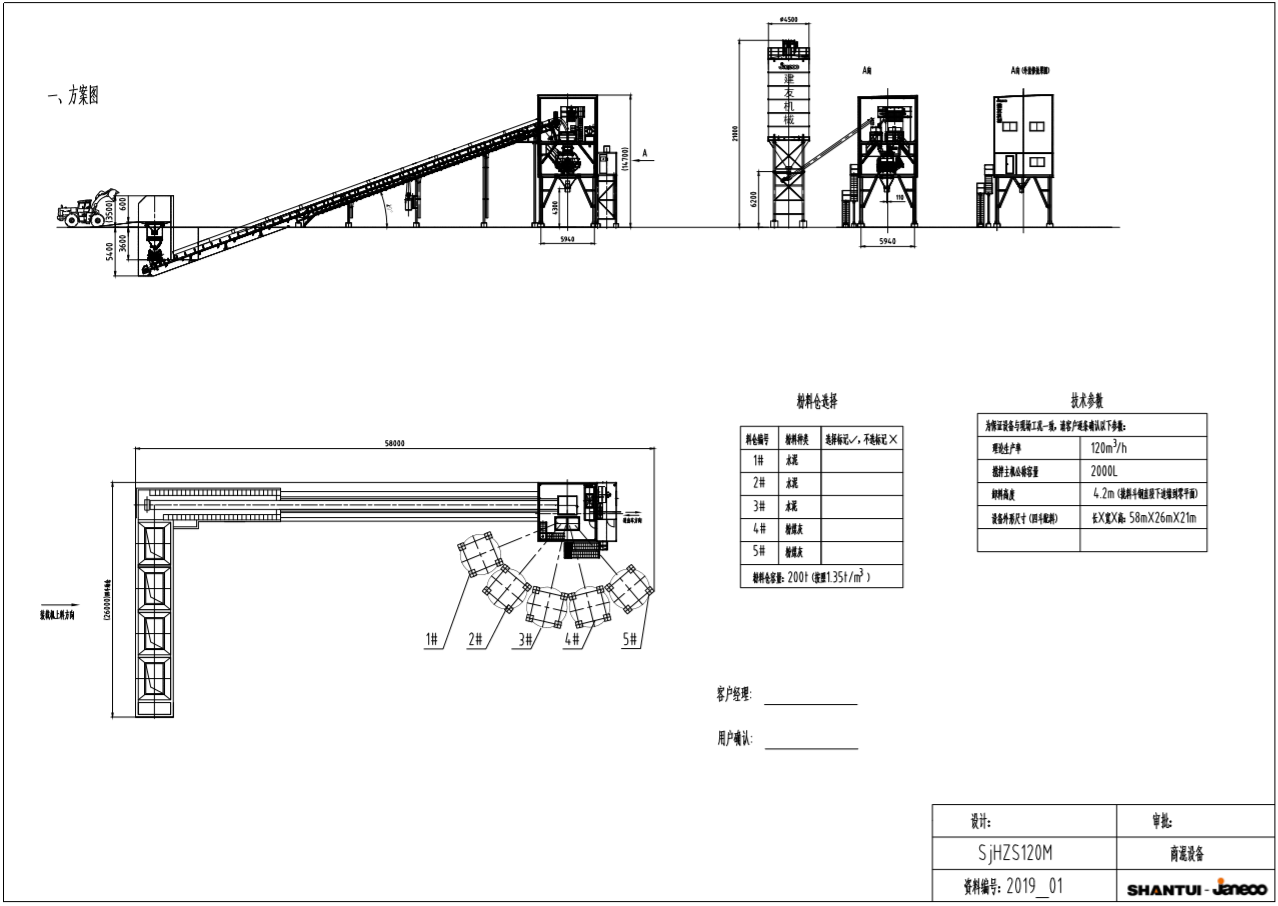

SjHZS120M configuration

|

No. |

Description |

Item |

Origin |

Qty |

Remark |

|

|

1 |

Aggregates batching system (4 hoppers ground type) |

Storage hopper |

Janeoo |

4 |

2 vibrator for 2 sand hoppers | |

| Weighing hopper(2000kg±2%) |

Janeoo |

4 |

||||

| cylinder |

SMC |

3×4 |

||||

| Sensor |

Toledo |

3×4 |

||||

| Belt machine(B:1000mm,P:5.5KW) |

Janeoo |

1 |

||||

|

2 |

Inclined belt machine |

Main support |

Janeoo |

1 |

|

|

| Driving device(P:37kW) |

Janeoo |

1 |

||||

| Belt(B:1000mm) |

Janeoo |

1 |

||||

| Water washing device |

Janeoo |

1 |

||||

|

3 |

Main building |

Main structure(2 layers platform) |

Janeoo |

1 |

|

|

| Discharging hopper |

Janeoo |

1 |

||||

| Bag type filter |

Janeoo |

1 |

||||

| Decoration |

Janeoo |

1 |

||||

|

4 |

High end mixer |

V:2.0 m3(P:2X37kW) |

Janeoo |

1 |

|

|

| Pneumatical Discharging structure |

Janeoo |

1 |

||||

| Pneumatic sealing system |

Janeoo |

1 |

||||

|

5 |

Middle hopper |

Storage hopper |

Janeoo |

1 |

|

|

| vibrator |

Janeoo |

1 |

||||

| cylinder |

SMC |

2 |

||||

|

6 |

Cement weighing system |

Weighing hopper(1000kg±1%) |

Janeoo |

1 |

|

|

| sensor |

Toledo |

3 |

||||

| Discharging valve(DN300) |

WAM |

1 |

||||

| vibrator |

Oli |

1 |

||||

|

7 |

Powder weighing system

|

Weighing hopper(400kg±1%) |

Janeoo |

1 |

|

|

| sensor |

Toledo |

3 |

||||

| Discharging valve(DN300) |

WAM |

1 |

||||

| vibrator |

Oli |

1 |

||||

|

8 |

Water weighing system |

Weighing hopper(500kg±1%) |

Janeoo |

1 |

|

|

| sensor |

Toledo |

1 |

||||

| discharging valve (DN150) |

Janeoo |

1 |

||||

| Water pump |

Janeoo |

1 |

||||

| Weighing valve(DN80) |

Janeoo |

1 |

||||

| Weighing pipes |

Janeoo |

1 |

||||

|

9 |

Additive weighing system |

Weighing hopper(50kg±1%) |

Janeoo |

1 |

Pe additive tank |

|

| sensor |

Toledo |

1 |

||||

| Discharging valve |

Janeoo |

1 |

||||

| Storage tank(V:10m3) |

Janeoo |

2 |

||||

| Additive pump |

Janeoo |

2 |

||||

| Weighing pipes |

Janeoo |

2 |

||||

|

10 |

Pneumatic system |

Air compressor(displacement:1.6 m3/min) | Atlas |

1 |

|

|

| Sotrage tank 1m3+0.3m3 |

Janeoo |

1套 |

||||

| Filter and valve |

SMC |

1 |

||||

|

11 |

Control room |

decoration |

Janeoo |

1 |

|

|

| Air conditioner |

Haier |

1 |

||||

|

12 |

Electrical system |

software |

Janeoo |

1 |

||

| Industrial computer and monitor |

Siemens |

1 |

||||

| UPS power |

Janeoo |

1 |

||||

| Printer |

OKI |

1 |

||||

| Electrical carbin and table |

Janeoo |

1 |

||||

| Main electric components |

schneider |

1 |

||||

| Monitoring system(1 monitor+4 cameras) |

Janeoo |

1 |

||||

| Optional | ||||||

|

No. |

Description |

Item |

Origin |

Qty |

Remark |

|

|

13 |

Cement silo |

200t |

Janeoo |

5 |

Cement density 1.35t/m3 |

|

| Maintenance platform |

Janeoo |

1 |

|

|||

|

14 |

Accessoies |

24㎡ filter |

Janeoo |

5 |

|

|

| Safe valve on the top |

Janeoo |

5 |

||||

| Level meter |

Janeoo |

2X5 |

||||

| Arch breaker |

Janeoo |

5 |

||||

| Manual valve |

Janeoo |

5 |

||||

|

15 |

Screw conveyor |

φ273X11m |

Janeoo |

3 |

cement |

|

| φ219X11m |

Janeoo |

2 |

powder |

|||

Product detail pictures:

Related Product Guide:

Adhering into the basic principle of "quality, assistance, effectiveness and growth", we have attained trusts and praises from domestic and worldwide client for China Supplier 50m3/H Mini Concrete Batching Plant - M series SjHZS120M specifications – Janeoo , The product will supply to all over the world, such as: Vietnam, South Africa, Paraguay, Really should any of these items be of interest to you, please let us know. We will be pleased to give you a quotation upon receipt of one's detailed specifications. We've our personal specialist R&D enginners to meet any of the requriements, We look forward to receiving your enquires soon and hope to have the chance to work together with you inside the future. Welcome to take a look at our organization.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.