China Cheap price Ce Mixing Concrete Batch Plant Supplier - Road base Material Mixing Plant – Janeoo

China Cheap price Ce Mixing Concrete Batch Plant Supplier - Road base Material Mixing Plant – Janeoo Detail:

Product Feature:

1.Concrete mixer adopts lining-plate-free mixing technology, so as to avoid wearing to the mixing blade and lining plate once and for all, making it easy for maintenance.

2.All materials are weighed up in electronic scale, which is controlled by variable frequency converter, featuring high weighing accuracy.

3.Adopting advanced centralized aggregate batching control system, so that batching accuracy and work efficiency of the whole plant can both be improved.

4.Modular structure, easy installation and rapid plant transfer.

5.Product purpose: Adapts to roadbed material pavement of all-grade roads, urban road, playground, wharf, etc.

Technical parameters

| Model | SjWBZ300 | SjWBZ400 | SjWBZ500 | SjWBZ600 | SjWBZ700 | SjWBZ800 | |

| Rated capacity(t/h) | 300 | 400 | 500 | 600 | 700 | 800 | |

|

Mixer |

Mixer rate power(kW) | 2X22 | 2X22 | 2X30 | 2X37 | 2X37 | 2X45 |

| Aggregate size(mm) | ≤50 | ≤50 | ≤50 | ≤50 | ≤50 | ≤50 | |

| Aggregate Bin Capacity (m³) | 4X12 | 4X12 | 4X12 | 5X12 | 5X12 | 5X15 | |

| Belt conveyance (t/h) | 300 | 400 | 500 | 600 | 700 | 800 | |

|

Weighing accuracy |

Aggregate | ±2% | ±2% | ±2% | ±2% | ±2% | ±2% |

| Cement | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | |

| Water | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | |

| Total power(kW) | 125 | 125 | 149 | 166 | 166 | 198 | |

| Discharge height(m) | 3.6 | 3.6 | 3.6 | 3.6 | 3.6 | 3.6 | |

All specification is subject to modification.

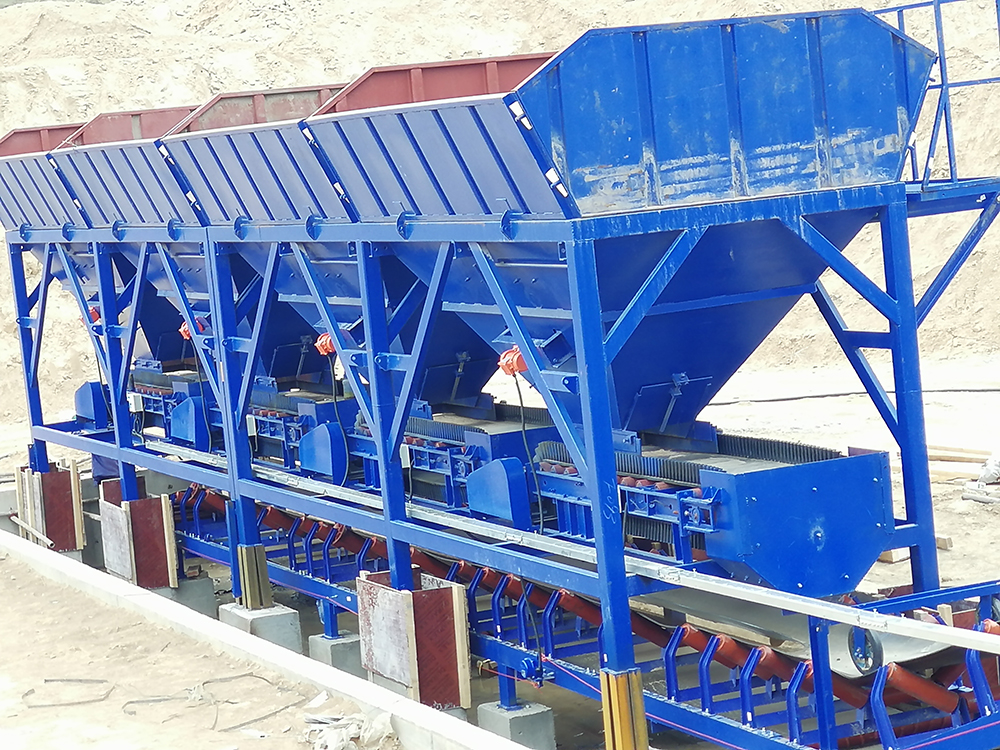

Product Components

Product detail pictures:

Related Product Guide:

We normally follow the basic principle "Quality Initial, Prestige Supreme". We've been fully committed to offering our consumers with competitively priced good quality merchandise, prompt delivery and professional support for China Cheap price Ce Mixing Concrete Batch Plant Supplier - Road base Material Mixing Plant – Janeoo , The product will supply to all over the world, such as: Mauritius, Senegal, Ghana, Should any of these items be of interest to you, please let us know. We'll be satisfied to give you a quotation upon receipt of one's detailed specifications. We have our personal experienced R&D enginners to meet any of one's requriements, We appear forward to receiving your enquires soon'and hope to have the opportunity to work together with you in the future. Welcome to check out our company.

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!